Sicheres Anlegen ist für Häfen, Werften und Schiffe unerlässlich. Um sowohl Schiffe als auch Kaimauern vor Schäden zu schützen, sind zuverlässige Fender erforderlich. Eine der wirksamsten Lösungen ist die Polyurethanschaum-Kotflügel. Diese Art von Kotflügeln verwendet einen speziellen Schaumstoffkern und eine robuste Polyurethanhaut, um eine hohe Energieabsorption und dauerhafte Leistung zu gewährleisten.

Aufbau und Hauptmaterialien

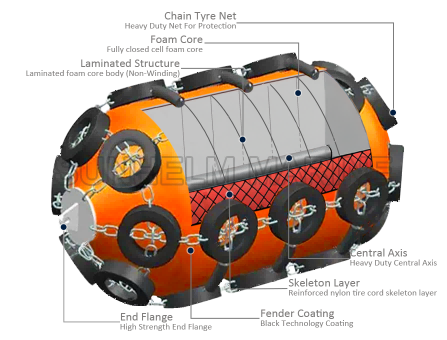

Ein Kotflügel aus Polyurethanschaum besteht aus drei Hauptkomponenten:

- Schaumstoffkern - Geschlossenzelliger Polyethylen- oder EVA-Schaumstoff, der so konzipiert ist, dass er beim Zusammendrücken Energie absorbiert, ohne Wasser aufzunehmen.

- Polyurethan-Haut - eine robuste, verschleißfeste Außenschicht, die vor Stößen, UV-Strahlen, Meerwasser und Öl schützt.

- Verstärkungsschicht - Oftmals befindet sich zwischen dem Schaumstoff und der Außenhaut ein Nylon- oder Fasernetz, das für zusätzliche Festigkeit sorgt.

- Endbeschläge - Stahlflansche oder Kettenringe für eine sichere Montage und Handhabung.

Durch diese Kombination entsteht ein solider, aber flexibler Fender, der unter rauen Meeresbedingungen extrem zuverlässig ist.

Wie funktionieren Polyurethan-Schaumstoff-Fender?

Wenn ein Schiff mit dem Fender in Berührung kommt, wird der geschlossenzellige Schaumstoff komprimiert und absorbiert die Aufprallenergie. Gleichzeitig verteilt der Fender die Kraft gleichmäßig, wodurch die Reaktionskraft zurück in den Schiffsrumpf übertragen. Da der Schaumstoffkern nicht wie luftgefüllte Fender die Luft entweichen lassen kann, bleibt die Leistung auch bei einer Beschädigung der Außenhaut erhalten.

Zu den wichtigsten Leistungsindikatoren gehören:

- Energieaufnahmefähigkeit (gemessen in kN-m).

- Reaktionskraft (die auf das Schiff übertragene Last).

- Maximale Durchbiegung (wie stark das Schutzblech zusammengedrückt werden kann).

- Auftrieb und Stabilität (sorgt dafür, dass der Fender unter allen Bedingungen schwimmfähig bleibt).

Vorteile von Fender aus Polyurethanschaum

Fender aus Polyurethanschaum sind wegen ihrer klaren Vorteile weit verbreitet:

- Unsinkbar und pannensicher - Auch wenn die Haut durchgeschnitten ist, funktioniert der Kotflügel weiter.

- Hohe Energieaufnahme bei geringer Reaktionskraft - ideal zum Schutz empfindlicher Rumpfstrukturen.

- Strapazierfähige Außenhaut - hohe Beständigkeit gegen Abrieb, UV-Strahlung, Meerwasser und Öl.

- Nicht-abfärbende Oberfläche - verhindert schwarze Gummiflecken auf Luxusyachten, Kreuzfahrtschiffen oder Marineschiffen.

- Geringe Wartung - Durch einfache Reinigung und kleinere Reparaturen bleiben sie viele Jahre lang einsatzfähig.

Beschränkungen und Überlegungen

Wie jede Ausrüstung haben auch Schaumstoffkotflügel einige Einschränkungen:

- Höhere Anfangskosten im Vergleich zu pneumatischen Fendern.

- Gewicht und Handhabung - große Einheiten können Kräne oder spezielle Ausrüstung für die Installation erfordern.

- Anwendungsspezifisches Design - Nicht jeder Liegeplatz oder Schiff-zu-Schiff-Einsatz erfordert Schaumstofffender, so dass die Wahl von den Bedingungen und dem Budget abhängt.

Gängige Typen und Größen

Kotflügel aus Polyurethanschaum gibt es in verschiedenen Formen und Ausführungen:

- Zylindrisch schwimmender Typ - die häufigste, die zum allgemeinen Anlegen verwendet wird.

- Genetztes Modell - Schaumstoffkotflügel, geschützt durch ein Ketten- und Reifennetz für den harten Einsatz.

- Donut-Kotflügel - so konstruiert, dass sie um einen Monopile schwimmen und sich frei mit der Bewegung des Schiffes drehen.

- Besondere Formen - für Offshore-Plattformen, Schwimmdocks oder den Einsatz in der Marine hergestellt.

Die Größen reichen von kleinen Einheiten für Yachten und Fischerboote bis hin zu massiven Fendern für VLCCs und Offshore-Terminals.

Anwendungen

Fender aus Polyurethanschaum eignen sich für eine Vielzahl von Einsätzen auf See:

- Liegeplätze in Häfen und Häfen - Schutz für Kaimauern und große Schiffe.

- Schiff-zu-Schiff-Transfers (STS) - Gewährleistung eines sicheren Kontakts zwischen Öltankern, LNG-Tankern oder Marineschiffen.

- Schwimmende Strukturen - auf Pontons, Schwimmdocks und Offshore-Windkraftanlagenplattformen verwendet.

- Notfall- und Bergungsmaßnahmen - bietet schnellen Schutz beim Abschleppen oder Retten.

FAQ

1. Nehmen Kotflügel aus Polyurethanschaum Wasser auf?

Nein, der geschlossenzellige Schaumstoffkern verhindert die Wasseraufnahme.

2. Sinkt der Kotflügel, wenn er durchstochen wird?

Nein, er bleibt funktionsfähig, weil der Schaumstoffkern den Auftrieb beibehält.

3. Wie lange dauern sie?

Bei ordnungsgemäßer Nutzung und Wartung haben viele Geräte eine Lebensdauer von über 10 Jahren.

4. Sind sie besser als pneumatische Schutzbleche?

Das hängt von der jeweiligen Situation ab. Fender aus Schaumstoff bieten eine höhere Sicherheit gegen Durchstiche, aber pneumatische Fender können für bestimmte Häfen kostengünstiger sein.

5. Kann die Außenhaut repariert werden?

Ja, oberflächliche Risse oder Schnitte können ausgebessert werden, ohne dass der gesamte Kotflügel ersetzt werden muss.