Выбирая крылья, вы покупаете защиту. Плавучие крылья с пенным наполнителем (часто называемые пенопластовыми) - это простой и надежный способ защиты судов и доков. В этом кратком руководстве объясняется, что это такое, почему многие порты выбирают их, как выбрать правильный тип и как покупать с уверенностью. Я излагаю все простым и практичным языком, чтобы вы могли действовать быстро.

Что это такое - простыми словами

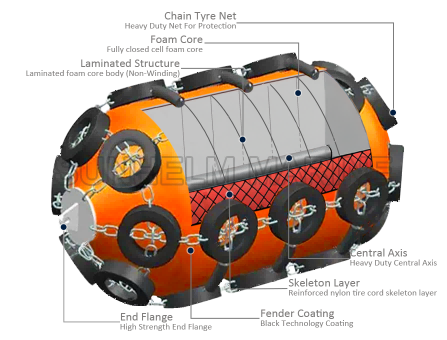

Крыло с пенопластовым наполнителем имеет твердый пенопластовый сердечник, обтянутый прочной резиной или эластомером. Пена поддерживает крыло на плаву и сохраняет его форму даже при повреждении внешней оболочки. В отличие от крыльев с воздушным наполнителем, они не зависят от давления.

Почему они нравятся многим судовладельцам и дизайнерам

- Они не сдуваются. Вы избежите внезапной потери защиты в случае прокола. Это снижает время простоя и риск на причале.

- Хорошее поглощение энергии при низком отскоке. Пенопластовые крылья поглощают энергию столкновения внутри своей сердцевины. Корабли, как правило, оседают на причал, а не отскакивают назад, что снижает ударную нагрузку на корпуса и причальные сооружения.

- Прочная внешняя кожа. Кожа устойчива к ультрафиолету, соли, маслу и обычному топливу. Это означает более долгий срок службы и меньший уход по сравнению с некоторыми альтернативами.

- Простой в обращении и установке. Большинство устройств поставляются со встроенными проушинами или проходными креплениями; вам не потребуется сложное оборудование для накачивания.

Распространенные типы и где они лучше всего работают

Производители выпускают пенопластовые крылья различных форм и размеров: цилиндрические, пончиковые (монопильные), сетчатые или бессетчатые, а также специальные подводные или свайные крылья. Для небольших судов или служебных причалов используйте небольшие, легкие пенопластовые крылья. Более крупные и длинные пенопластовые крылья используются там, где суда причаливают на скорости или где требуется большая энергоемкость. В каталогах продукции приведены показатели энергопоглощения и силы реакции, которые можно использовать при проверке конструкции крыльев.

Как выбрать правильное крыло

Сосредоточьтесь на нескольких цифрах и условиях, а не на названиях брендов:

- Поглощение энергии (EA): Убедитесь, что EA крыла при стандартном сжатии (часто 60%) соответствует энергии, необходимой для сценария швартовки судна. В таблицах производителей приведены значения EA для разных размеров.

- Сила реакции: Более низкая сила реакции лучше подходит для небольших или хрупких причалов и для быстрой швартовки. Крылья из пенопласта обычно имеют меньшую силу реакции, чем альтернативные варианты из твердой резины.

- Расстояние между крыльями и их количество: Несколько больших крыльев часто работают лучше, чем множество маленьких. Проверьте рекомендации по расстоянию между крыльями в каталогах поставщиков.

- Условия эксплуатации: Если на причале будут присутствовать углеводороды, лед или сильное ультрафиолетовое излучение, выбирайте материал обшивки и усиления, рассчитанные на эти опасности.

Установка, обслуживание и срок службы

Устанавливайте их с надлежащими цепями, кандалами и опорными пластинами. При регулярном осмотре следует обращать внимание на порезы кожи, истирание или потерю проушин. Поскольку сердцевина крыльев состоит из твердой пены, вам не придется следить за давлением, и вы можете рассчитывать на меньшее ежедневное обслуживание по сравнению с пневматическими крыльями. Тем не менее, планируйте проверки и заменяйте обшивку или фитинги, если они сильно изношены.

Советы по покупке - получайте выгоду, а не просто низкую цену

- Попросите производителей Таблицы сил сопротивления и реакций для точного размера, который вы планируете купить. Сравните эти цифры, а не только размеры.

- Проверьте, предлагает ли поставщик OEM или пользовательские размеры и сроки их изготовления. Многие авторитетные производители изготавливают на заказ длину, диаметр и материал кожи.

- Запросите рекомендации или тематические исследования по аналогичным причалам (те же размеры судов, то же воздействие волн/течений). Хорошие поставщики покажут установки.

- Уточните условия поставки, гарантию и наличие запасных частей. Немного более высокая цена при надежной гарантии часто позволяет сэкономить деньги в долгосрочной перспективе.

Быстрый пример ROI (простая логика)

Правильно подобранные пенные крылья уменьшают количество ударов по корпусу судна, повреждений краски и ремонта причалов. Эта экономия быстро возрастает по сравнению с единовременной стоимостью качественной системы пенных крыльев. Во многих портах более качественные крылья сокращают счета за ремонт и задержки судов - и защищают вашу репутацию безопасного причала.

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

В: Подходят ли пенопластовые крылья для тяжелых судов?

О: Да - но выбирайте крылья большего диаметра и длины с более высоким EA и проверьте показатели силы реакции.

В: Можно ли использовать пенопластовые крылья в холодных или маслянистых водах?

О: Да, выбирайте материал для кожи, рассчитанный на устойчивость к низким температурам и углеводородам. Попросите производителя предоставить данные испытаний.

В: Нужен ли им тщательный уход?

О: Нет. Они нуждаются в плановых осмотрах и периодической замене кожи или фитингов, но не в проверке давления.