إذا كان الرصيف الخاص بك يشهد رسو السفن بزاوية، أو تأرجح المد والجزر، أو انعطافات الرورو أو مناورات ضيقة، فإن المصدات المخروطية تستحق نظرة فاحصة. فهي ليست فقط "مختلفة من الناحية الجمالية" عن المصدات الخلوية أو الأسطوانية - فشكلها يغير من كيفية تشوه المطاط تحت بزاوية تأثير، وهذا يعطي فوائد حقيقية وقابلة للقياس في امتصاص الطاقة وضغط الهيكل ومقاومة القص.

سأشرح أدناه بلغة واضحة, لماذا تتعامل المصدات المخروطية مع ضغط الزوايا بشكل أفضلوما الذي يعنيه ذلك بالنسبة لتصميم رصيفك البحري، ونصائح عملية للاختيار/التركيب التي تهم بالفعل في الموقع.

ملخص سريع

تستخدم المصدات المخروطية خلية مخروطية مدببة تشبه المخروط تعمل على توزيع الأحمال وإعادة توجيهها عندما تصطدم السفينة بزاوية. تحافظ هذه الهندسة على ثبات الرفراف، وتسمح له بالانحراف أكثر بكثير مع قوة رد فعل قصوى أقل، وتقاوم القص الجانبي - بحيث تبطئ السفن دون تعريض الرصيف أو الهيكل لأحمال نقطية عالية. هذه السمات تجعل مصدات مطاطية مخروطية مخروطية مثالية حيثما تكون زوايا الرسو أو مدى المد والجزر أو مناورات السفن متغيرة.

قصة الهندسة - سبب أهمية الشكل المخروطي

فكّر في الحاجز المخروطي على أنه "إسفين ذكي" من المطاط:

- أنف مدبب وقاعدة عريضة: يخلق الوجه الضيق الذي يلتقي بالوعاء والبطن الأعرض في الخلف مسار ضغط تدريجي. ينتج التلامس المبكر قوة منخفضة؛ ومع زيادة الضغط تشتبك القاعدة الأكبر وتحمل الحمل - وهذا يعطي رد فعل أكثر سلاسة وتزايداً تدريجياً بدلاً من الارتفاع المفاجئ. ويحسن هذا السلوك التدريجي من امتصاص الطاقة لكل وحدة ارتفاع.

- مستقر تحت الإمالة: عندما يصطدم الوعاء بزاوية، فإن هندسة المخروط تعيد توزيع الحمل بشكل طبيعي بدلاً من تركيزه في زاوية واحدة. وهذا يحافظ على المطاط من الطي أو القص خارج الموضع ويحافظ على سلوك الضغط المقصود حتى في الزوايا الكبيرة. وتظهر الشركات المصنعة والاختبارات أن المصدات المخروطية تظل ثابتة عند زوايا ضغط أكبر من العديد من أنواع المصدات الأخرى.

- قدرة انحراف عالية: يمكن للمصدات المطاطية المخروطية المخروطية أن تنضغط كثيرًا (يقتبس المصنعون انحرافات في نطاق ~70-74% لبعض التصميمات فائقة المخروط)، لذلك فهي تمتص الطاقة على مدى شوط أطول. شوط أطول + قوة ذروة أقل = كبح ألطف على الوعاء ومخاطر تلف موضعي أقل.

أداء ضغط الزاوية: المكاسب التقنية

- انخفاض ذروة التفاعل لنفس الطاقة الممتصة. هذا هو الهدف العملي: إيقاف السفينة بهدوء دون قوى ضخمة على الرصيف أو الهيكل. تعطي الهندسة المخروطية نسبة ممتازة لامتصاص الطاقة/قوة رد الفعل (E/R).

- مقاومة أفضل للقص. القاعدة العريضة والمظهر الجانبي الداخلي يقاومان الانزلاق الجانبي وأحمال القص الشائعة أثناء إرساء الزوايا، لذلك غالباً ما تحتاج إلى أجهزة ثانوية أقل للتحكم في القص.

- يعمل عند زوايا التلامس الصغيرة والكبيرة. تحافظ التصميمات المخروطية العلوية على الأداء حتى زوايا التلامس الصغيرة (أبلغت الشركات المصنعة عن أداء مستقر حتى 10 درجات تقريبًا) ولا تزال تؤدي أداءً جيدًا في الزوايا الأكبر - وهي نقطة أساسية للأرصفة التي لا تشهد وصولًا عموديًا مثاليًا.

- استخدام فعال للمساحة والمواد. نظرًا لأن المصدات المخروطية تحزم المزيد من الانحراف وسعة الطاقة في قالب مضغوط، يمكنك في كثير من الأحيان تحقيق نفس الحماية بوحدات أقصر/أقل حجمًا من المصدات الخلوية ذات تصنيف الطاقة المتساوي. وهذا يساعد عندما تكون مساحة الرأس أو عمق واجهة الرصيف محدودة.

حيث تكون المصدات المخروطية أكثر منطقية

استخدم المصدات المخروطية عندما ترى أيًا منها في موجز التصميم:

- متكرر رسو بزاوية (عبّارات، دوارة، أرصفة متعددة الأغراض).

- كبير نطاقات المد والجزر التي تغير هندسة التلامس.

- أوجه الرصيف المدمجة حيث تحتاج إلى امتصاص عالي للطاقة مع عمق تركيب محدود.

- التعامل مع الأرصفة سفن كبيرة (الحاويات والناقلات والرحلات البحرية) ولكن بزوايا اقتراب غير منتظمة أو بروز محدود للرفارف.

نصائح عملية للتصميم والتركيب

- ضع في اعتبارك الإطارات أو الألواح الأمامية إذا كنت تتوقع قصًا شديدًا أو ترغب في حماية طلاء بدن السفينة - يتم تزويد العديد من الأنظمة المخروطية بوسادات وإطارات ذات واجهات وإطارات منخفضة الاحتكاك للتحكم في التلامس وتقليل التآكل.

- التحقق من بدل الانحراف في جدول الحاجز الخاص بك (لا تفترض أن الحاجز يمكن أن ينضغط بشكل غير محدود). استخدم بيانات الشركة المصنعة لمنحنى E/R الفعلي بدلاً من التخمين من الحجم وحده.

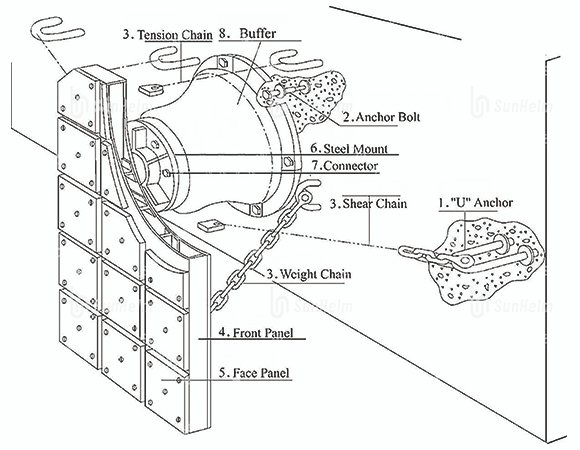

- راقب تخطيط المرساة والمسمار. القاعدة الأعرض توزع الحمولة - يجب أن تتطابق أنماط التثبيت وأحجام المسامير مع أحمال القاعدة الأكبر بدلاً من حمولة الوجه الضيقة.

- أضف سدادات التحميل الزائد للحالات القصوى. تشتمل بعض تصميمات "المخروط الفائق" على نقاط توقف ميكانيكية لتجنب الضغط الزائد أثناء الصدمات الشديدة العرضية. وهذا يحمي كلاً من الحاجز والرصيف.

- خطة الوصول إلى التفتيش على الخطة. حتى المخاريط القوية تحتاج إلى فحوصات منتظمة للتحقق من التآكل أو التشقق أو تآكل المرساة. إن قولبتها المكونة من قطعة واحدة تجعل عملية الاستبدال سهلة ومباشرة ولكنها تخطط للرفع والمناولة.

قائمة مراجعة قصيرة لاختيار الرفارف المخروطية مقابل الرفارف الأخرى

- إذا كان تأثيرات بزاوية متكررة → لصالح المخروط.

- إذا كان الحد الأقصى الطاقة لكل وحدة ارتفاع المسائل → يفوز المخروط.

- إذا كنت بحاجة إلى أقل قوة رد فعل ممكنة لمستوى الطاقة → المخروط → ممتاز.

- إذا كان لديك رسو متعامد طويل وبطيء في المياه العميقة وتريد التكرار → قد تكون المصدات الخلوية → جيدة (ولكن يمكن للمخاريط في كثير من الأحيان أن تضاهي الأداء في حزمة أقصر).

الأسئلة الشائعة

Q - هل المصدات المخروطية أفضل دائمًا من المصدات الخلوية؟

أ - ليس دائماً. تتفوق المصدات المطاطية المخروطية في الأداء عندما يكون الرسو بزاوية أو في حالة الإسقاط المحدود أو المنشآت المدمجة. بالنسبة للرسو المتعامد ذي الطاقة العالية جداً حيث يكون لديك مساحة، لا تزال المصدات الخلوية خياراً قوياً. استخدم حساب الطاقة/التفاعل للمقارنة.

Q - هل تحتاج الرفارف المخروطية إلى صيانة خاصة؟

أ - لا توجد صيانة غريبة. افحصها بحثاً عن التآكل، والعوامل الجوية، وتآكل المرساة وتآكل اللفائف. إذا كنت تستخدم الألواح الأمامية أو سدادات التحميل الزائد، أدرجها في جدول الفحص.

Q - هل يمكنني تعديل المخاريط على رصيف موجود؟

أ - في كثير من الأحيان نعم. تكون المصدات المخروطية مدمجة ويمكن تركيبها بشكل فردي أو متعدد. تحقق من السعة الهيكلية للرصيف ونمط المسامير؛ قد تحتاج إلى إطار للتكيف مع مواضع التثبيت الموجودة.

Q - هل تزيد المصدات المخروطية من ضغط الهيكل؟

أ - التشوُّه التدريجي للمخروط عادةً يقلل ذروة ضغط هيكل السفينة مقابل بعض المصدات الأكثر صلابة لأنها توزع الطاقة على شوط أطول. ومع ذلك، تحقق دائماً من ضغط الهيكل مع منحنى E/R الفعلي لحجم المصدات الذي اخترته.

خلاصة القول

بالنسبة للأرصفة التي تشهد الاقتراب بزاوية، أو التقلبات الكبيرة في المد والجزر، أو بروز الحاجز المحدود،توفر المصدات المخروطية أداءً فائقًا في ضغط الزوايا: انحراف أكبر، وامتصاص أفضل للطاقة، وذروة رد فعل أقل، وثبات أعلى في القص. إنها تطور حديث للمصدات الخلوية المصممة لحماية كل من الرصيف والسفينة في ظروف الرسو الفوضوية الواقعية. إذا كان موجز التصميم الخاص بك يتضمن أيًا من السيناريوهات المذكورة أعلاه، فقم بإجراء مقارنة لجدول المصدات جنبًا إلى جنب باستخدام منحنيات E/R الخاصة بالمصنعين - ستجد غالبًا أن المخاريط توفر حماية مساوية أو أفضل مع مساحة أصغر.