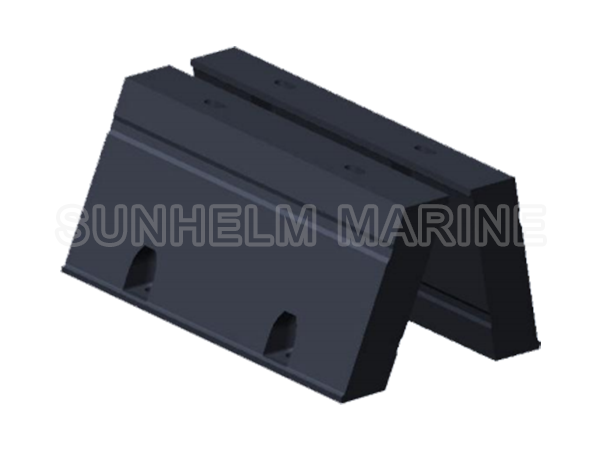

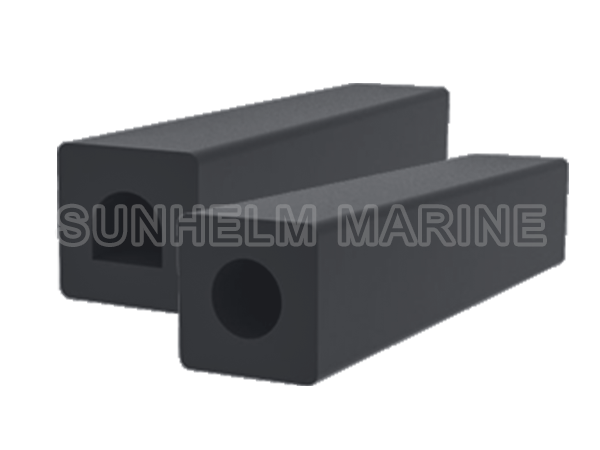

SFW D TYPE RUBBER FENDER

SFW D Type Rubber Fender

SFW D Type rubber fenders are used as fenders for tugboats, work boats and other vessels. SunHelm Marine provides a round hole for D-type rubber fenders to increase wall thickness and durability, and to provide the D fender with the ability to secure it with flat steel. D fender can be operated (cutting, drilling, and pre-bending). SunHelm Marine can also customize the D-type fenders for your needs. The D-type fender is a commonly used rubber fender worldwide and is produced in a variety of designs and sizes through extrusion. The rear cover of this type of shield makes it easy to mount the D shield on a variety of surfaces to protect ships and docks.

- Marinas.

- Multiple purpose fendering.

- Tug Boats and Workboats.

- Small boat berths.

- Impact absorption.

- Protection for marine vessels.

D Type Fender Characteristics

Simple & easy installation.

Customized sizes.

Wide range of applications.

Highly durable rubber fender.

Popular D type extrusion.

Tough rubber bumper.

Long lengths can be customized.

Multi- colors can be customized.

SFW D Type Fender Construction

Want the product information or solutions?

Want to ship quickly?

No problem!

info@sunhelmmarine.com

+86 (0)531 88255160

WhatsApp: +86 152 5419 6767

SFW D Type Fender Specifications And Related Resources

SFW D Type Rubber Fender Application

Marinas|Multiple purpose fendering|Tug Boats and Workboats|Small boat berths|Impact absorption|Protection for marine vessels

SFW D Type Rubber Fender

SFW D Type Rubber Fender

SFW D Type Rubber Fender

SFW D Type Rubber Fender

International Leading SFW D Type Rubber Fender Manufacturer

SunHelm Marine Co., Ltd. is a Chinese manufacturer specializing in maritime products. SunHelm Marine currently has several large-scale modern factories and R&D centers. SunHelm Marine mainly produces pneumatic fenders, marine rubber fenders, foam fenders, hydro-pneumatic fenders, marine airbags, marine salvage airbag, caisson moving airbags and other products.

Based on ship industry chain, SunHelm Marine has expanded its market layout, main business involves ship mooring and berthing, marine engineering, port construction and other fields. SunHelm provides customers with systematic, comprehensive and creative services.

After nearly 20 years of development, product and technology applications have covered more than 80 countries and regions in 7 continents, NANHAI became the well-known brand in the world.

ISO 9001

ISO 14001

ISO 45001

SGS

Fixed Fender Type

SFA CELL RUBBER FENDER

SHD CONE RUBBER FENDER

SSA CYLINDRICAL RUBBER FENDER

SEB ARCH RUBBER FENDER

SFW D TYPE RUBBER FENDER

SMW W TYPE RUBBER FENDER

SFC ELEMENT RUBBER FENDER

SBD SQUARE RUBBER FENDER

SDD- D RUBBER FENDER

TUGBOAT FENDERS

Our Products

We are in the business of developing high performance marine rubber protections. According to 20 years researching and developing, SunHelm Marine has abundant experiences in custom designing marine fenders and airbags to meet specific application needs. We are pride with ourselves on our quality and stand behind our products.

YOU GOT QUESTIONS,

WE GET THE ANSWERS YOU NEED

We commitment that we will try our best to solve all the questions for our customer. We welcome and valued your advice to us. We are not only your supplier but also your key of success and your partner of business.