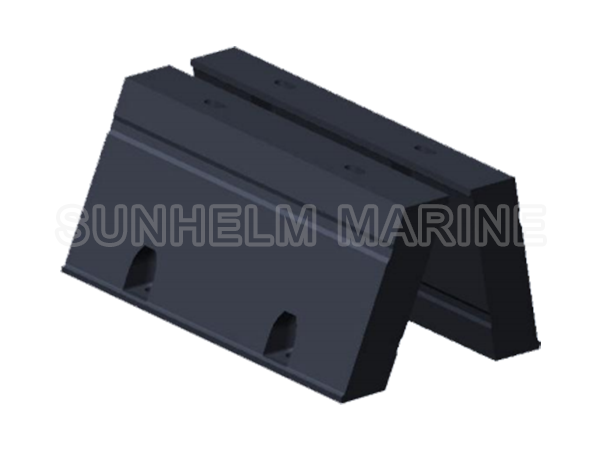

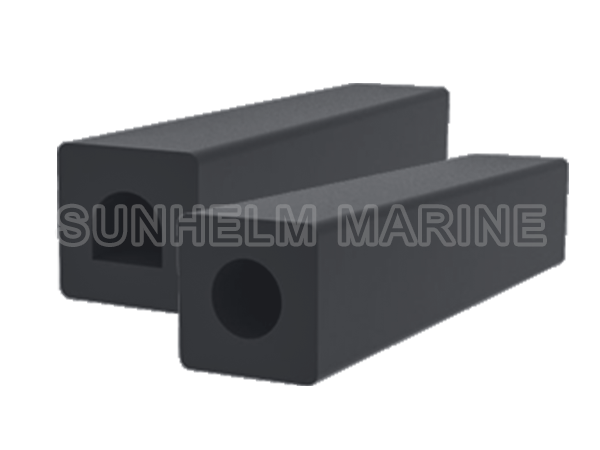

SFC Element Type Rubber Fender

SFC Element Rubber Fenders are fully molded rubber legs with embedded mounting plates.Based on V Fenders but with separate legs,SFC Element Fenders provide high layout flexibilities when installed behind steel panels or where mounting space is limited. SFC Elements fenders are versatile and can be combined in unlimited combinations of length and direction.The simplest Unit SFC Element fender system is the UE-V fender, with pairs of legs and a UHMW-PE non-marking shield.SFC Element Fenders are available in heights between 250 and 1,600 mm, in standard lengths ranging from 500 to 2,000 mm.

- Tanker Berths.

- RoRo and cruise ships.

- Container & Bulk Terminals.

- Small craft berths.

- General Cargo Terminals.

- Navy|Barge.

Element Fender Characteristics

Versatile modular system.

Highly efficient shape.

Symmetrical or asymmetrical fixings.

Strong in lengthwise shear.

Good energy absorption to reaction force ratio (E/R).

High energy absorption per fender weight .

Modular and compact design with small footprint.

Vertical and horizontal mounting, typically in pairs.

Pile Fender design may use single units.

Easy to install,maintenance & replacement.

International Leading SFC Element Type Rubber Fender Manufacturer

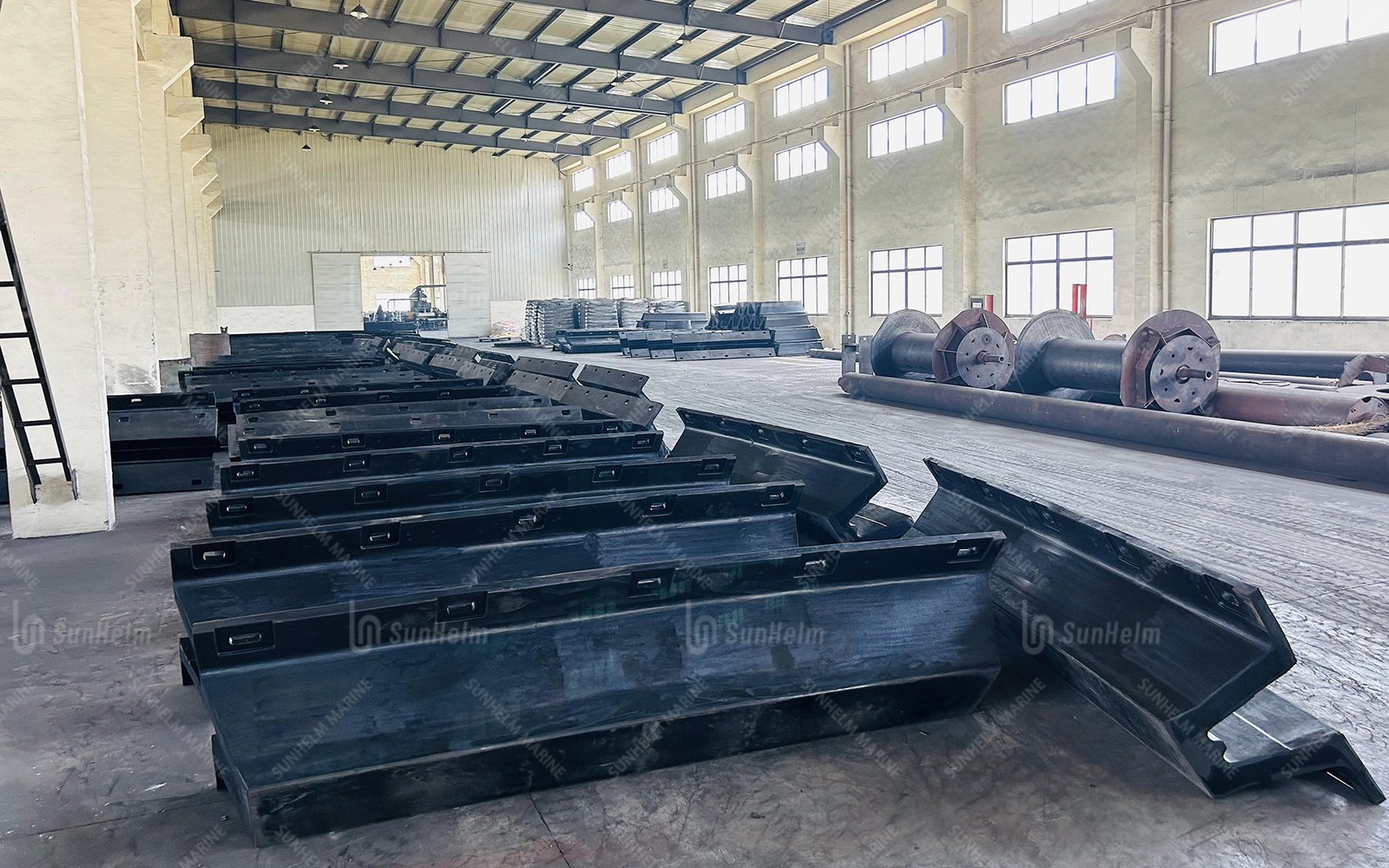

SunHelm Marine Co., Ltd. is a Chinese manufacturer specializing in maritime products. SunHelm Marine currently has several large-scale modern factories and R&D centers. SunHelm Marine mainly produces pneumatic fenders, marine rubber fenders, foam fenders, hydro-pneumatic fenders, marine airbags, marine salvage airbag, caisson moving airbags and other products.

Based on ship industry chain, SunHelm Marine has expanded its market layout, main business involves ship mooring and berthing, marine engineering, port construction and other fields. SunHelm provides customers with systematic, comprehensive and creative services.

After nearly 20 years of development, product and technology applications have covered more than 80 countries and regions in 7 continents, NANHAI became the well-known brand in the world.

Our Products

We are in the business of developing high performance marine rubber protections. According to 20 years researching and developing, SunHelm Marine has abundant experiences in custom designing marine fenders and airbags to meet specific application needs. We are pride with ourselves on our quality and stand behind our products.