Tugboat Rubber Fender

Tugboat fenders are mainly used for the bow and stern of the tugboat, and act as an anti-collision buffer device when the tugboat is working. It is a highly wear-resistant and durable solid rubber fender. Common tugboat fenders are M type, W type, cylindrical and keyhole type. Tug boat fenders can be used in very harsh environments, because of the nature of the tugboat's work, it may be used in working environments with ultra-high temperatures and exposure to chemicals. SunHelm’s tug fenders are made of natural rubber, certified by PIANC2002, which is sturdy and durable. It is the high-quality rubber tug fender you are looking for.

Tugboat Cylindrical Fender

Tug Cylindrical Fenders are often used as the primary pushing fenders on the bow or stern of modern tugboat. Their round shape is ideal for working with large bow fl ares, but are equally good for pushing fl at-sided vessels.Tug Cylindrical Fenders own long continuous or spigot-joined lengths which can be customized according to user requirements.

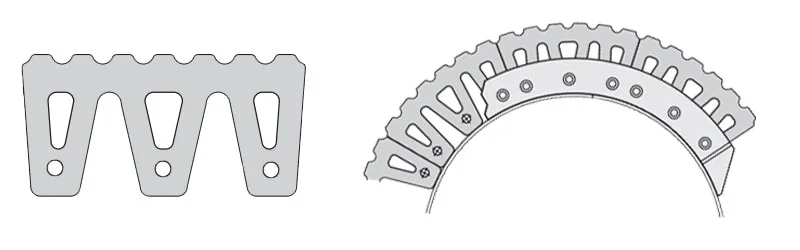

Tugboat M Fender

M Fenders have a large and fl exible contact face which exerts a low pressure during pushing operations. The grooves provide extra grip and the triple legs give a strong attachment to the tug. M Fenders can also be fitted around tight curves, whilst their relative low weight adds to tug stability.

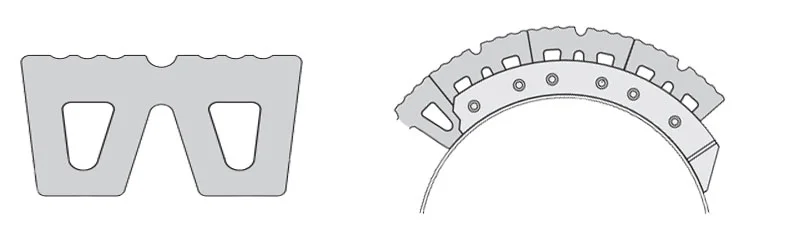

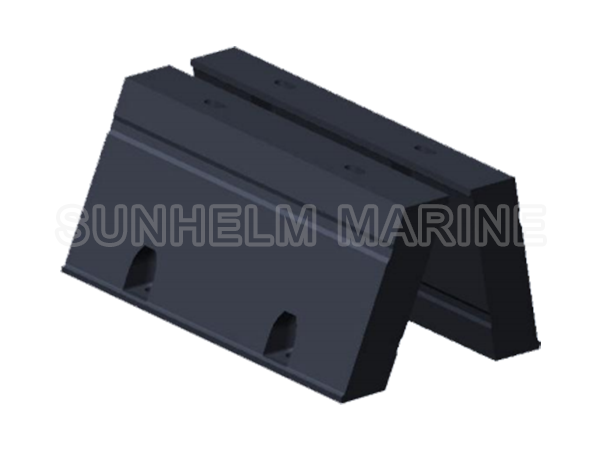

Tugboat W Fender

W Fenders are made for the most extreme operating conditions which is one of the most successful fenders for tugs in the world today. It has a unique open bore design which makes installation very simple. The flexible legs allow W Fenders to be curved around most hull shapes.

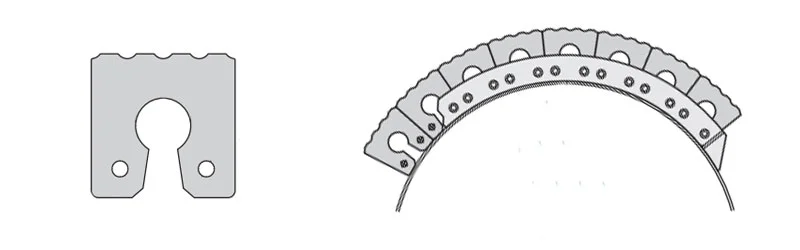

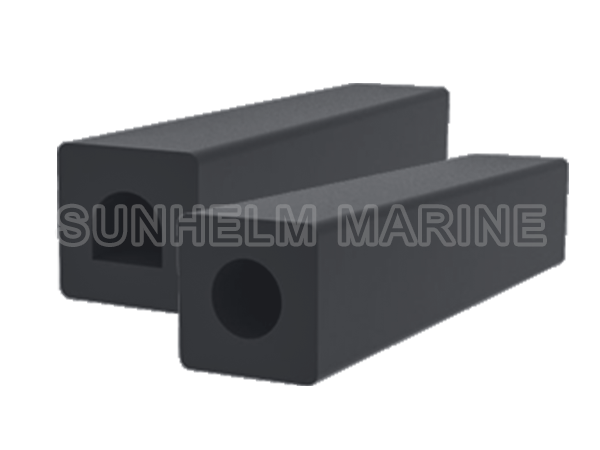

Tugboat Block Fender

Block Fenders have a traditional ‘keyhole’ profile which is strong and ideal for heavy-duty applications. There is a choice of grooved or fl at face fenders depending on the required friction levels. Where very low friction is needed, Block Fenders can also be made as composite fenders with integral UHMW-PE panel. This is useful for tugs that operate in heavy swell and storm conditions.

International Leading Tugboat Rubber Fender Manufacturer

SunHelm Marine Co., Ltd. is a Chinese manufacturer specializing in maritime products. SunHelm Marine currently has several large-scale modern factories and R&D centers. SunHelm Marine mainly produces pneumatic fenders, marine rubber fenders, foam fenders, hydro-pneumatic fenders, marine airbags, marine salvage airbag, caisson moving airbags and other products.

Based on ship industry chain, SunHelm Marine has expanded its market layout, main business involves ship mooring and berthing, marine engineering, port construction and other fields. SunHelm provides customers with systematic, comprehensive and creative services.

After nearly 20 years of development, product and technology applications have covered more than 80 countries and regions in 7 continents, NANHAI became the well-known brand in the world.

Our Products

We are in the business of developing high performance marine rubber protections. According to 20 years researching and developing, SunHelm Marine has abundant experiences in custom designing marine fenders and airbags to meet specific application needs. We are pride with ourselves on our quality and stand behind our products.