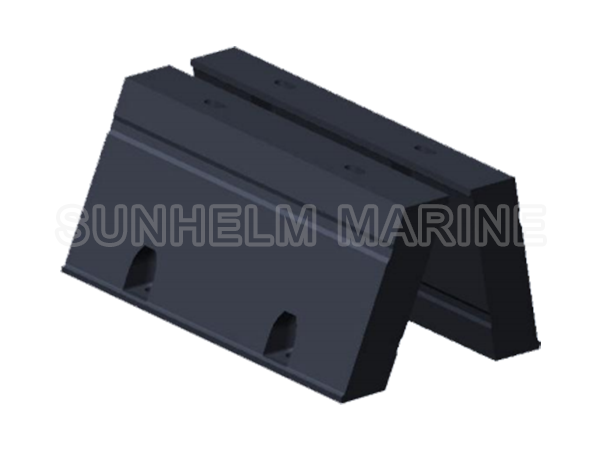

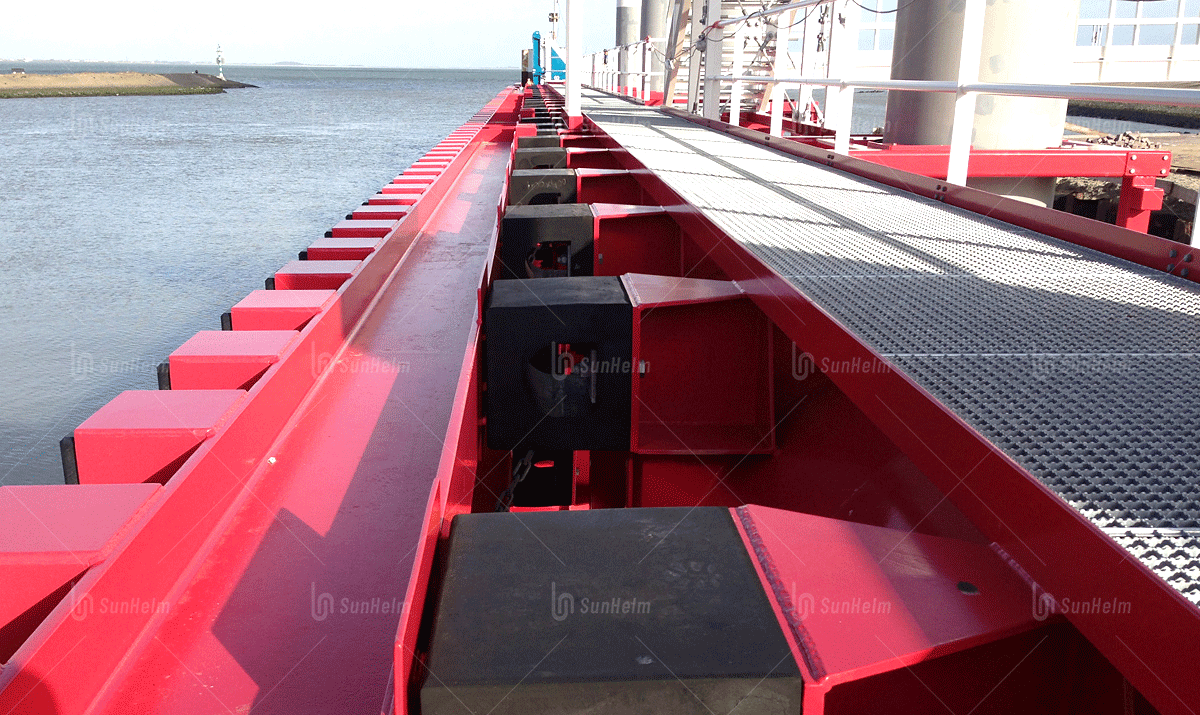

SBD Square Rubber Fender

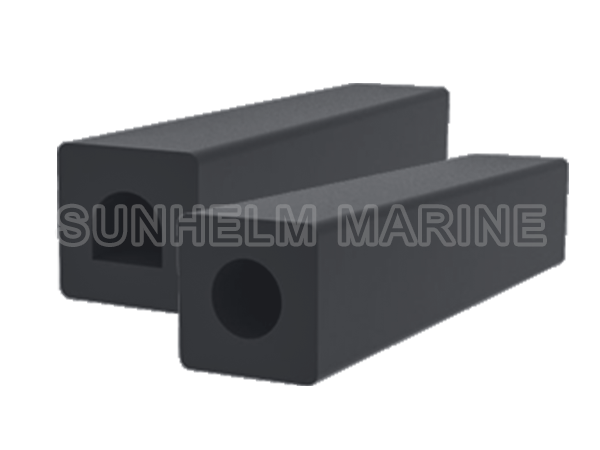

SBD Square Rubber fenders are produced in various designs and sizes and they can be used for a wide range of purposes. The production takes place by means of extrusion. When compared to D-fenders, SBD fenders are used when a more rigid and stronger bumper is required for use in more severe conditions. SunHelm produces SBD fenders in a standard range and most common sizes are kept in stock and can be delivered at short notice. Extruded fenders are simple rubber profiles, usually attached with bolts to the structure. Extrusions can be made in virtually any length then cut and drilled to suit each application. Pre-curved sections and special sizes are available on request. Usually black in colour.

- Jetties and wharves for small craft.

- Tugs and workboats.

- Pontoon protection.

- Inland waterways.

- General purpose fendering.

SBD Square Fender Characteristics

Good performance during angle berting.

Applicable for all kinds of docks,quays,and ships.

Can be used in harsher environments.

Can be supplied in long lengths and be cut to length, angle cut at the ends.

High energy absorption and reasonable reaction force.

Easy to install, simple and diverse installation methods.

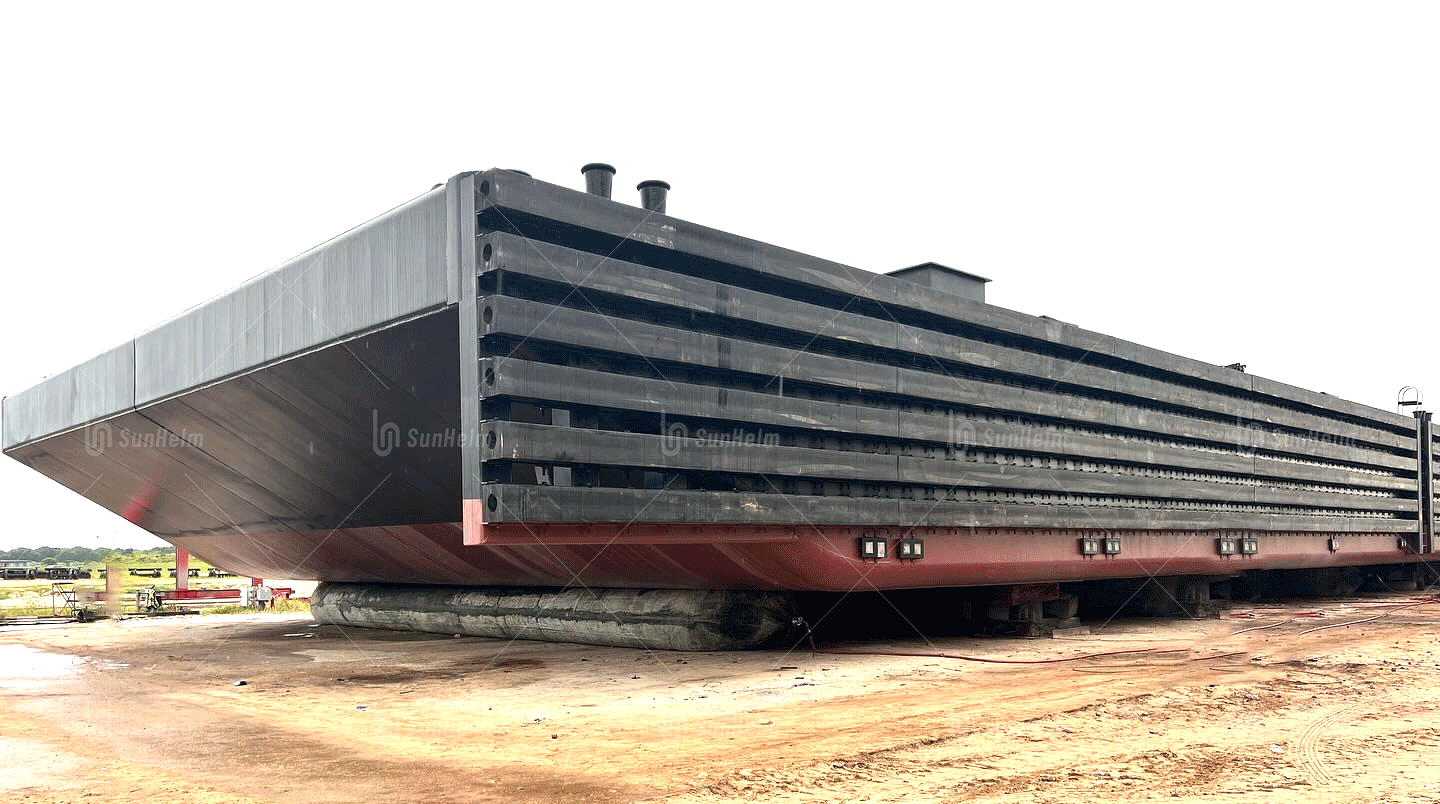

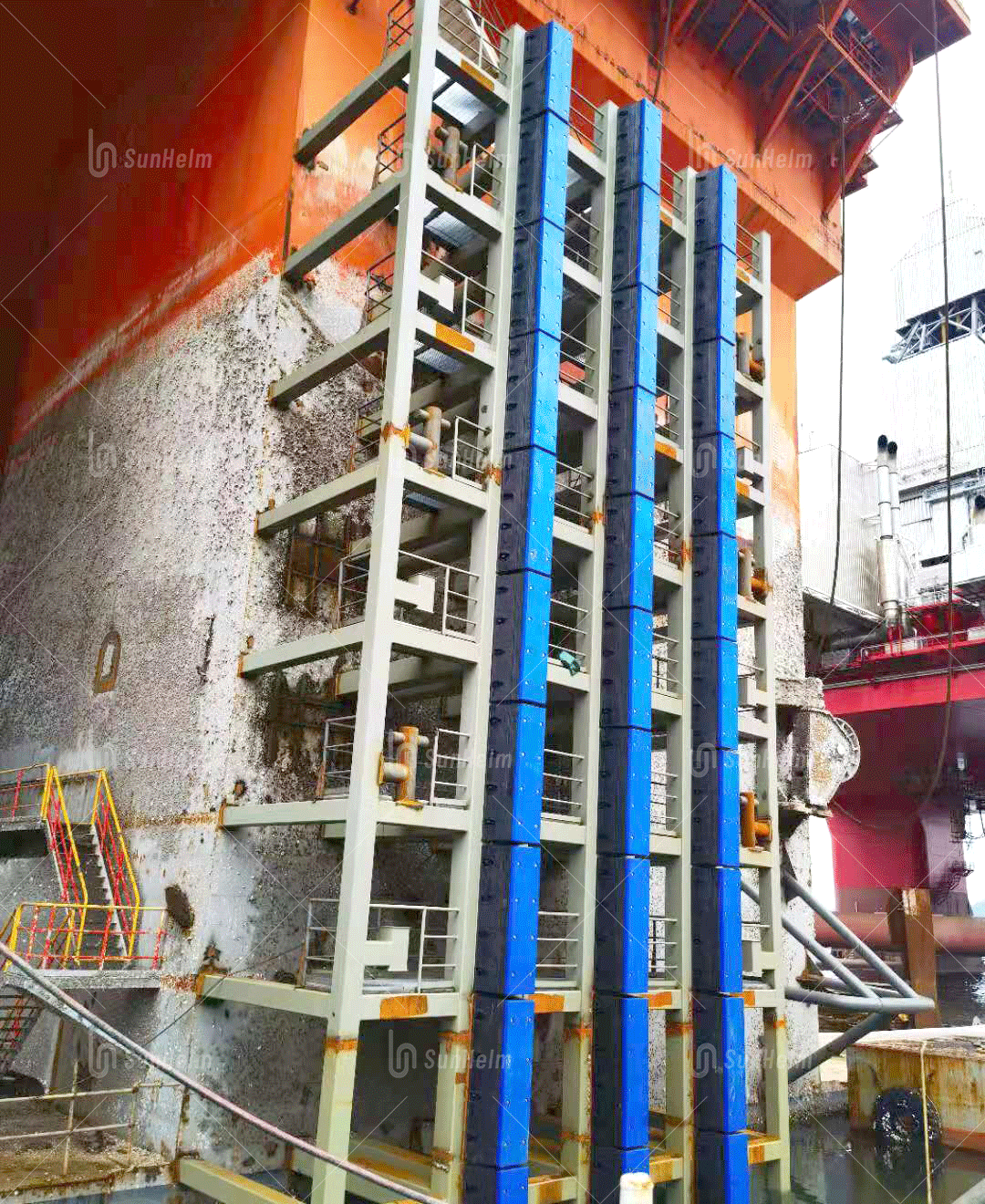

Berthing Cases

SunHelm Marine's 20-year engineering legacy in marine fender systems encompasses cutting-edge pneumatic, foam-core, and fixed rubber technologies, delivering scientifically optimized energy absorption and unmatched berthing safety for vessels of all sizes.

SBD Square Fender Construction

YOU GOT QUESTIONS,

WE GET THE ANSWERS YOU NEED

Want to ship quickly?

No problem!

International Leading SBD Square Rubber Fender Manufacturer

SunHelm Marine Co., Ltd. is a Chinese manufacturer specializing in maritime products. SunHelm Marine currently has several large-scale modern factories and R&D centers. SunHelm Marine mainly produces pneumatic fenders, marine rubber fenders, foam fenders, hydro-pneumatic fenders, marine airbags, marine salvage airbag, caisson moving airbags and other products.

Based on ship industry chain, SunHelm Marine has expanded its market layout, main business involves ship mooring and berthing, marine engineering, port construction and other fields. SunHelm provides customers with systematic, comprehensive and creative services.

After nearly 20 years of development, product and technology applications have covered more than 80 countries and regions in 7 continents, SunHelm Marine became the well-known brand in the world.