Let’s Get Straight to It – Why Do So Many Ports and Shipyards Use Foam Fenders?

Foam fenders are basically “floating cushions” made of closed-cell foam inside and a tough outer skin. They absorb a lot of impact when a vessel berths, and even if the skin gets punctured, they won’t sink. That’s why they are so popular.

What Do Foam Fenders Look Like and Why Are They Reliable?

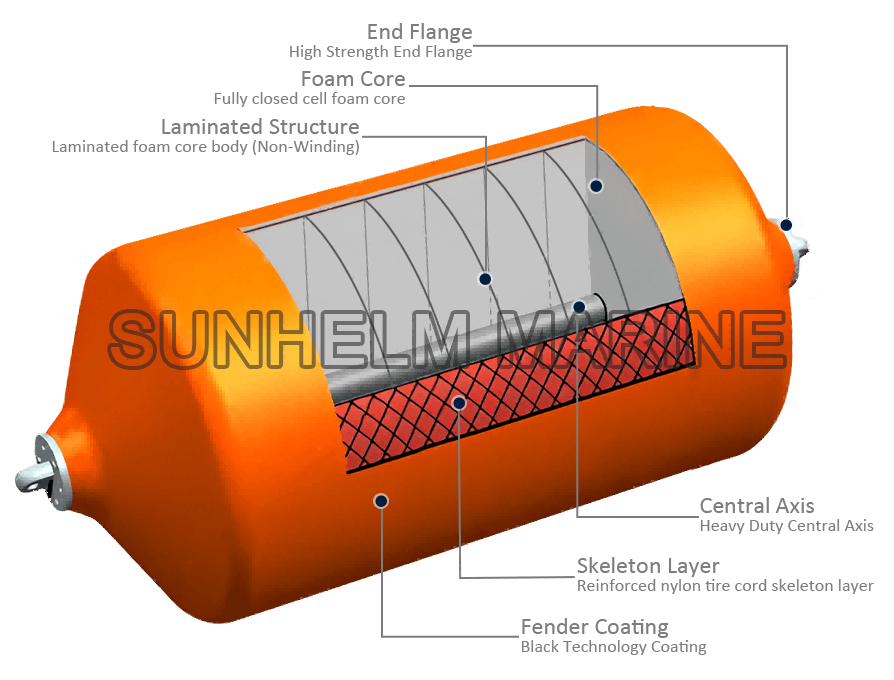

Most foam fenders have a closed-cell foam core wrapped in a reinforced polyurethane (PU) skin. Sometimes we add nylon fiber or other layers for extra strength. The closed-cell foam doesn’t take in water, so even if the skin gets damaged, the fender keeps floating. This makes them safe and long-lasting.

Why Go Custom? (Buying a Standard Size Isn’t Always Enough)

Different vessels have different berthing energy, hull shapes, dock structures, tide levels, and operations. A yacht marina and a bulk carrier berth need completely different fender specs, reaction forces, and mounting setups. Custom fenders give you the right protection for both the vessel and the dock. Many brands offer different foam densities, sizes, and fittings to match these needs.

What Can Be Customized? (Practical List)

- Size – Diameter and length based on your vessel’s energy and contact area.

- Foam density/grade – Low density for soft-hull protection (yachts, cruise ships), high density for heavy berthing (cargo ships).

- Outer skin material and color – PU is common; color and logo can match your brand.

- Mounting style – Chain nets, tire nets, hooks, steel bars, or hanging systems depending on site conditions.

- Extra protection – Tire rings, wire ropes, and quick-change fittings for easier maintenance.

How Sunhelm Handles It

- Quick assessment – You tell us your vessel type, berthing setup, and docking speed. Photos or videos help.

- Design & calculation – We calculate berthing energy and hull pressure, then choose the best size, foam density, and reaction force.

- Sample & approval – We can provide a sample or 3D design for confirmation.

- Production & reinforcement – We use closed-cell high-density foam with tough PU skin, and add chain nets or tire nets if needed.

- Install & follow-up – We guide you through installation or do it on-site, then give maintenance tips.

So yes — you can fit foam fenders to oddly shaped vessels without a problem. Customizing means the “shield” fits the ship perfectly, keeps things safer, and often saves money in the long run.

Quick Tips

- “Do they break easily?” – No. The thick skin and closed-cell foam core mean they stay afloat even if punctured.

- “Can you print our logo?” – Yes. We can match Pantone colors and add your company logo.

FAQ

Q1: How long does it take to make a custom foam fender?

A: It depends on complexity and quantity. Most orders take a few weeks to a few months. Small or simple orders are faster; larger or more complex ones take longer.

(Tip: Send us your vessel data early to speed things up.)

Q2: Will a foam fender take in water or sink?

A: No. The closed-cell foam core won’t absorb water. Even if the skin is cut, it will keep floating.

Q3: How do I choose the foam density for my vessel?

A: As a rule, low density gives low reaction force and is better for soft-hull vessels like yachts. High density handles more energy for bulk carriers or busy ports. We calculate it for you.

Q4: Are they hard to maintain?

A: Not at all. Just check the skin for damage, make sure chains or fittings are tight, and repair or replace the skin if needed.

Q5: Can Sunhelm make samples or small trial orders?

A: Yes. We can produce small-batch samples and help you test them before you commit to a full order.