When you walk along a pier or berth, you may notice heavy steel posts mounted on the quay — these are marine bollards. They might look simple, but they are critical components in keeping vessels safely moored. At Sunhelmmarine, we design and supply bollards for ports, shipyards, and terminals worldwide, ensuring ships stay secure in all kinds of conditions.

Why Marine Bollards Matter

A marine bollard is a fixed mooring point that transfers the mooring line load from a vessel to the berth structure. Without them, ships would struggle to stay in position against wind, waves, currents, and tidal forces. Proper bollards not only improve safety but also protect the quay structure and reduce maintenance costs. They work together with marine fenders to create a complete berthing system.

Common Types of Marine Bollards

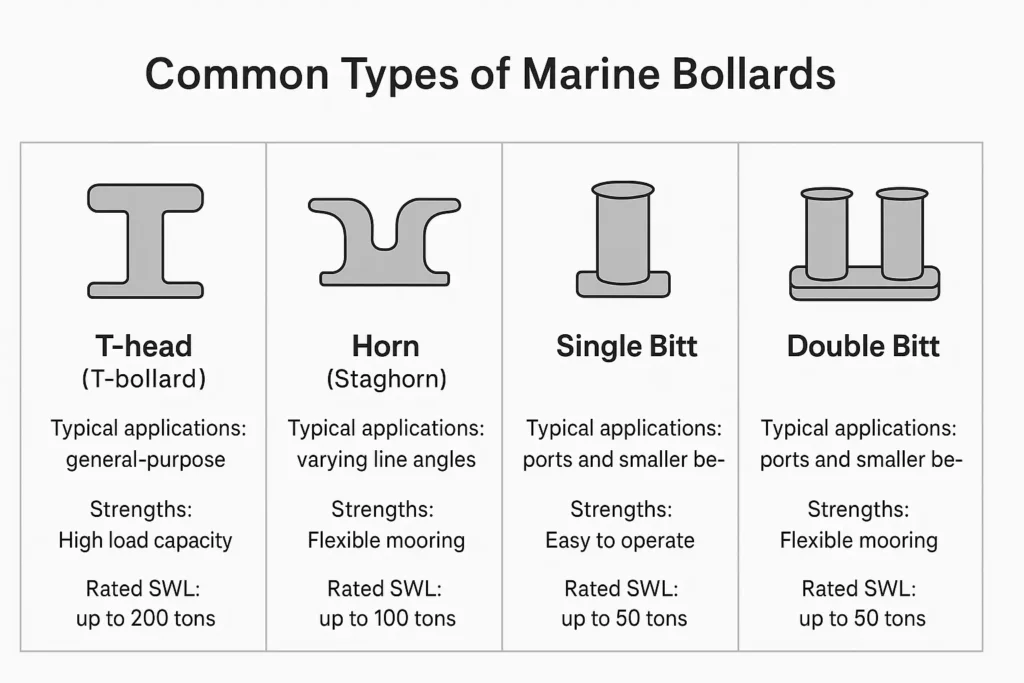

Marine bollards come in several designs, each with its own advantages:

- T-head (T-bollard) – Offers high load capacity and works well with multiple line angles.

- Horn or Staghorn – Double curved horns help secure lines at different approach angles.

- Single Bitt – A straightforward, vertical post ideal for smaller berths or lighter vessels.

- Double Bitt – Two vertical posts allow flexible mooring arrangements.

Choosing the right type depends on vessel size, mooring pattern, and quay layout.

Materials & Surface Protection

Most marine bollards are made from cast steel, ductile cast iron, or fabricated steel. The choice depends on load requirements and project budget.

To ensure long life, surface protection is essential:

- Galvanizing – Hot-dip or thermal spray zinc for corrosion resistance.

- Coating systems – Epoxy primer plus polyurethane topcoat for UV and impact protection.

- Wear-resistant tops – For areas where mooring lines create heavy abrasion.

Anchor bolts and base plates must be corrosion-protected too, often with stainless steel or galvanized steel.

Key Performance Terms You Should Know

When selecting a bollard, you’ll often see the term SWL (Safe Working Load). This is the maximum load that the bollard can safely handle. It’s different from the ultimate breaking load, which is much higher.

Other factors include:

- Mooring line type (synthetic, steel wire, HMPE)

- Mooring angle — horizontal and vertical

- Load direction and frequency

Understanding these terms ensures you select the right bollard for your berth.

How to Choose the Right Marine Bollard

Here’s a quick selection checklist:

- Vessel size and displacement – Larger ships need higher SWL.

- Berth environment – Consider wind, wave, and current forces.

- Tidal range – Influences mooring angles and line tension.

- Mooring frequency – High-traffic berths need heavy-duty designs.

- Base structure – Ensure quay or jetty can handle bollard loads.

- Corrosion protection – Match coating to local climate and water conditions.

At Sunhelmmarine, we help clients run these calculations and choose bollards that match both operational needs and budget.

Layout & Spacing Basics

Bollards are typically installed at regular intervals along a berth, with closer spacing at corners or points where forces are concentrated. They must align with the mooring plan so that ships can connect lines without overloading a single bollard. Bollard placement should also coordinate with fender locations, gangways, and mooring equipment.

Installation Essentials

Installing a marine bollard involves:

- Preparing the base – Ensure concrete or steel structure meets load requirements.

- Positioning anchor bolts – Accurate alignment is critical.

- Grouting – Fills gaps, increases stability, and prevents water ingress.

- Torque tightening – Bolts must be tightened to specified torque and rechecked after load tests.

Common mistakes include bolt misalignment, insufficient grouting, or skipping post-installation inspection.

Inspection & Maintenance

Even the toughest bollards need regular care:

- Visual checks – Look for cracks, coating damage, or bolt loosening.

- Annual maintenance – Recoat, replace damaged bolts, and update signage.

- After extreme events – Inspect after storms, collisions, or overload incidents.

A good maintenance program extends bollard life and ensures mooring safety.

Compliance & Documentation

Every bollard installation should come with:

- Material certificates

- Coating records

- Torque test reports

- As-built drawings

Following industry standards and local port regulations ensures safety and legal compliance.

Sunhelmmarine Solutions

At Sunhelmmarine, we manufacture a wide range of marine bollards — from T-head to double bitt — all customizable in SWL, coating system, and mounting style. We also offer:

- Technical support for design and layout

- On-site installation guidance

- Long-term after-sales service and spare parts

Our products are trusted by ports, terminals, and shipyards worldwide for their strength, durability, and reliability.

Case Snapshots

- RoRo Terminal Upgrade – Installed horn bollards with 150-ton SWL for improved line handling.

- Bulk Cargo Port – Supplied T-head bollards for large bulk carriers, optimized for high tidal range.

- Shipyard Retrofit – Replaced old bollards with ductile iron double bitts for longer service life.

FAQs: Marine Bollards

Q: What’s the difference between a marine bollard and a cleat?

A: Bollards handle much higher loads and are designed for commercial and industrial berths, while cleats are smaller and common on yachts or small docks.

Q: How many lines can I tie to one bollard?

A: It depends on the SWL and bollard design, but generally two or three lines are common.

Q: How do I know if my bollard needs replacement?

A: Look for visible cracks, bent structures, or severe corrosion.

Q: Can I upgrade a bollard’s SWL?

A: No — SWL depends on the bollard design and foundation; upgrading requires a new unit and possibly stronger foundations.

Q: Does coating type really matter?

A: Yes. The wrong coating can lead to premature corrosion and costly repairs.

Download & Next Steps

Want to make sure your berth has the right mooring equipment? Download our Marine Bollard Selection Checklist and Installation Inspection Sheet.

Contact Sunhelmmarine today to get a tailored marine bollard solution for your port or shipyard.