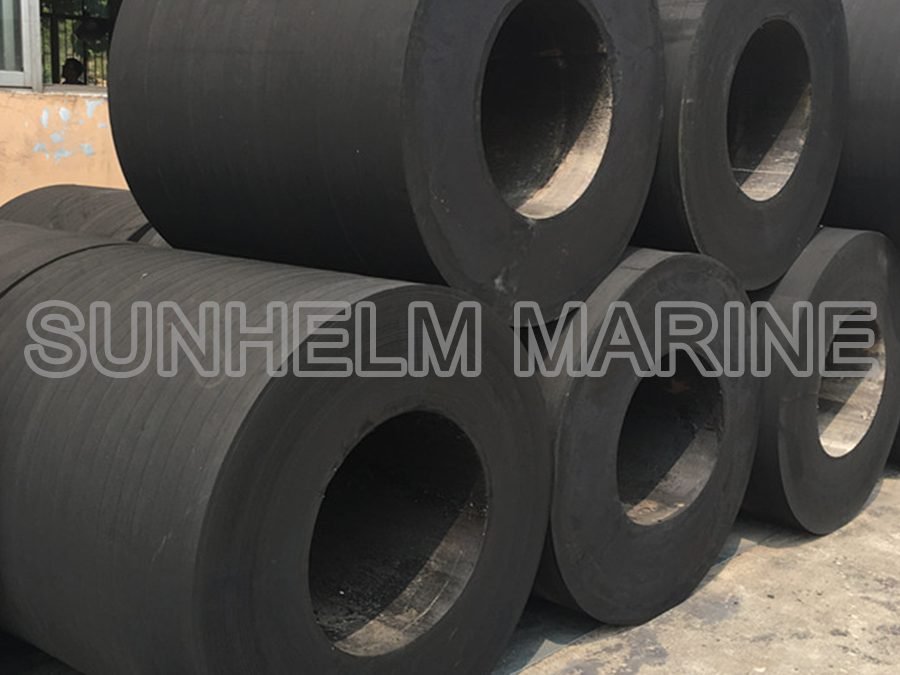

Cylindrical fenders are essential protective devices widely used in marine operations to safeguard ships, docks, and other structures during berthing. These marine fenders absorb impact energy and prevent damage to both vessels and port facilities. For companies like Sunhelm, specializing in high-quality ship fenders, maintaining these cylindrical fenders is crucial to ensure longevity and optimal performance.

Why Cylindrical Fenders Maintenance Is Necessary and Urgent

Regular maintenance of cylindrical fender is vital to prevent costly damages and extend their service life. Imagine a busy port where ships constantly dock—without proper care, the fenders can degrade, lose elasticity, or develop cracks. This not only jeopardizes vessel safety but can also lead to expensive repairs and downtime.

For example, a shipping company once ignored routine fender inspections and suffered hull damage from a worn-out fender during a night berth. This incident delayed operations and increased costs significantly. That’s why understanding and implementing simple maintenance tips is urgent for every marine facility or shipowner relying on cylindrical fenders.

Key Cylindrical Fenders Maintenance Tips

1. Regular Visual Inspections

Inspect your cylindrical fender frequently for signs of wear and tear such as cracks, abrasions, or deformation. Early detection helps prevent small issues from escalating.

2. Clean Fenders to Remove Debris and Marine Growth

Salt, algae, and barnacles can accumulate on fenders, affecting their flexibility and strength. Use fresh water and appropriate brushes to clean them regularly.

3. Check and Maintain Proper Inflation Pressure (for pneumatic types)

Some cylindrical fenders are inflatable. Always monitor the air pressure and ensure it stays within manufacturer recommendations to maintain optimal shock absorption.

4. Monitor and Repair Surface Damage Promptly

Minor cuts or punctures should be repaired immediately using manufacturer-approved kits. Ignoring damage can compromise the fender’s protective function.

5. Lubricate Moving Parts

If your fenders have chains, shackles, or connectors, apply lubrication to prevent rust and ensure smooth operation.

6. Store Spare Fenders Properly

When not in use, store the cylindrical fenders in a shaded, dry area to avoid UV damage and unnecessary wear.

Why Choose Sunhelm for Your Ship Fenders?

Sunhelm offers durable, high-performance marine fenders designed to withstand harsh maritime conditions. Our cylindrical fender come with detailed maintenance guidelines and reliable customer support, helping you protect your vessels and port infrastructure efficiently.

People Also Ask About Cylindrical Fender Maintenance

Q: How often should I inspect my cylindrical fender?

A: It’s best to inspect them monthly, especially after severe weather or heavy usage.

Q: Can cylindrical fenders be repaired if damaged?

A: Yes, minor damage can often be repaired using specialized kits, but severe damage may require replacement.

Q: What is the difference between cylindrical and other types of marine fenders?

A: Cylindrical fenders are simple, durable, and cost-effective, often used in ship-to-ship or ship-to-dock applications, while other types like cone or cell fenders offer different impact absorption characteristics.

Q: How do I maintain inflatable cylindrical fenders?

A: Regularly check air pressure, clean the surface, and repair any punctures quickly.

Maintaining your cylindrical fenders doesn’t have to be complicated. With these easy tips, you can ensure your marine fenders last longer and perform better, keeping your ships and docks safe every time they berth. For trusted quality and expert advice, turn to Sunhelm—the name you can rely on in ship fenders.