When winter hits and temperatures drop below zero, choosing the right foam fenders becomes more than just a matter of price — it’s about performance, durability, and safety. The wrong choice could mean cracked fenders, damaged hulls, and costly downtime. So, should you go with EVA foam fenders or polyurethane foam fenders for your cold-weather operations? Let’s break it down in a practical, easy-to-digest way.

Why Winter Demands Special Attention for Foam Fenders

Winter operations are a completely different game compared to summer. When you’re docking or transferring cargo in freezing conditions, fenders face extra challenges:

- Ice and snow make surfaces slippery and increase collision risks.

- Low temperatures can make some materials brittle and prone to cracking.

- Frequent docking during harsh weather accelerates wear and tear.

- Floating ice chunks can cause unexpected cuts and abrasions.

If your fenders can’t handle the cold, you’ll end up with compromised energy absorption, reduced rebound, and possibly even structural damage to your vessels or terminals.

How Foam Fenders Work

Before comparing EVA and polyurethane, let’s quickly recap how foam fenders are built:

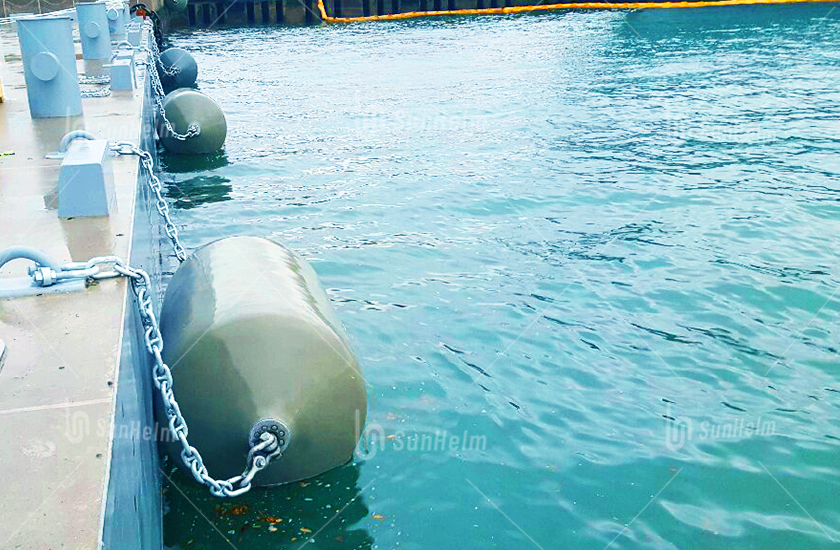

- Closed-cell foam core: This absorbs impact energy while preventing water from seeping in — even if the outer layer gets scratched.

- Tough outer skin: Usually polyurethane or similar coatings that resist cuts, abrasions, and UV damage.

- Floating design: Foam-filled fenders naturally float and are easy to position, even in rough seas.

- Chain nets and accessories: In harsher conditions, extra protection like chain nets or nylon jackets can extend service life.

EVA vs Polyurethane: Head-to-Head Comparison

Here’s where things get interesting. Both EVA and polyurethane foam fenders work well, but they shine in different scenarios — especially in winter.

1. Low-Temperature Flexibility

- EVA foam fenders stay soft and flexible even at temperatures as low as -30°C.

- Polyurethane foam cores can work well, but performance depends on density and formulation. Without the right spec, they may stiffen and lose rebound.

Verdict: EVA wins if you’re operating in extreme cold.

2. Resistance to Cuts and Abrasions

- EVA cores offer balanced tear resistance but rely on the skin for heavy-duty protection.

- Polyurethane outer skins are extremely tough and handle scraping against ice edges, rough hulls, and concrete docks better.

Verdict: PU-coated fenders hold up better against physical damage.

3. Energy Absorption and Reaction Force

Energy absorption (EA) and reaction force (RF) are critical for fender performance. Both EVA and polyurethane foam fenders can be engineered for high EA with low RF, but EVA cores generally maintain performance more consistently in freezing conditions.

4. Maintenance and Lifespan

- EVA foam fenders are easy to repair, and surface cracks rarely compromise the core.

- PU-coated fenders have longer-lasting skins but are slightly more complex to patch on-site.

5. Weight and Handling

EVA foam cores are lighter, which makes installation and relocation easier — especially useful if your operations involve frequent redeployment during winter.

Summary Table

| Feature | EVA Foam Fenders | Polyurethane Foam Fenders |

|---|---|---|

| Low-temp flexibility | ★★★★★ Excellent | ★★★★ Depends on spec |

| Cut resistance | ★★★★ Good | ★★★★★ Excellent |

| Energy absorption | ★★★★★ Stable in cold | ★★★★ Good |

| Maintenance | ★★★★ Simple | ★★★ Requires prep |

| Weight | Lighter | Slightly heavier |

| Best for | Extreme cold, floating ice | High-abrasion environments |

How to Choose the Right Foam Fender for Winter

Here’s a quick checklist to make your decision easier:

- Temperature range → Below -20°C? Go EVA.

- Docking frequency → High-frequency STS ops? Consider PU-coated skins.

- Ice conditions → Thin ice? EVA works well. Heavy drifting ice? PU skins are safer.

- Maintenance capacity → No on-site repair teams? PU-coated fenders last longer between services.

- Budget and lifecycle cost → EVA usually has a lower upfront cost, but PU-coated fenders may save money long-term.

Winter Maintenance Tips for Foam Fenders

Even the best fenders need proper care in freezing conditions:

- Inspect regularly: Check for cracks, cuts, and surface wear after each docking.

- Avoid sharp tools: When removing ice, never use picks or hammers directly on the skin.

- Use protective nets: Chain or nylon nets protect against ice cuts and extend lifespan.

- Store smartly: If fenders are seasonal, keep them in dry, shaded storage to prevent hardening.

Common Mistakes to Avoid

- Choosing based only on EA: Low reaction force is equally important.

- Ignoring the outer skin: The wrong coating can fail in icy environments.

- Skipping protective gear: Unprotected fenders are prone to cuts from floating ice.

- Using summer specs in winter: Standard-density foam might fail below freezing.

Final Thoughts

If you’re operating in extreme cold with floating ice, EVA foam fenders are usually your safest bet thanks to their flexibility and consistent performance. On the other hand, if your biggest challenge is abrasion from rough docks or frequent scraping, a polyurethane-coated foam fender will last longer and require less maintenance.

The smartest approach? Combine EVA foam cores with thick polyurethane skins for the best of both worlds.

FAQ

Q1: Are foam fenders suitable for sub-zero temperatures?

Yes — especially EVA foam fenders, which perform well even at -30°C.

Q2: Which lasts longer in winter, EVA or polyurethane?

PU-coated fenders tend to have tougher skins, but EVA cores remain more flexible in extreme cold.

Q3: Can I repair a damaged foam fender in freezing weather?

Yes, but it’s easier with EVA cores since surface cracks rarely affect performance.

Q4: Do I need special coatings for icy waters?

A polyurethane outer skin is highly recommended to resist cuts and abrasions from ice.