Are you tired of dealing with leaking pneumatic fenders and constant maintenance? Looking for foam filled marine fenders for sale that last longer and require less attention? You’re in the right place. In this guide, we’ll explain everything you need to know before buying, installing, and maintaining foam-filled fenders — in simple language and a practical tone.

Key Advantages at a Glance

- No air, no leaks – The closed-cell foam core means there’s no risk of deflation, even if the outer skin is damaged.

- High energy absorption – The foam core disperses impact energy efficiently, protecting both vessels and dock structures.

- Durable outer skin – Made from polyurethane or synthetic rubber, the skin resists UV, saltwater, oil, and abrasives.

- Customizable sizes – Choose diameter, length, energy ratings, and skin material based on your specific needs.

- Low maintenance – No air checks, minimal upkeep, and long service life even in harsh environments.

Product Specifications to Consider

Before making a purchase, confirm these parameters with your supplier:

- Diameter and length

- Energy absorption (EA) and reaction force

- Outer skin material and thickness

- Connection type (through-chain, pad-eye, flange, etc.)

- Operating temperature and chemical resistance

Tip: Always base your selection on vessel displacement, berthing speed, and required energy absorption.

Typical Applications

- Commercial ports and cargo terminals

- Cruise terminals and passenger docks

- Shipyards and dry docks

- Offshore oil & gas platforms

- Ship-to-ship (STS) transfer operations

- Bridge construction and floating project protection

Foam-Filled vs. Other Fenders

- Pneumatic fenders: Great for soft initial contact, but they can deflate if punctured. Foam-filled fenders are more reliable and require less care.

- Solid rubber fenders: Strong and simple, but they absorb less energy and often weigh more.

- Tire or sliding fenders: Cheap and easy, but they wear faster and provide less protection overall.

Installation, Anchoring & Maintenance Guide (Detailed Section)

Correct installation and regular maintenance ensure the best performance and longest lifespan. Here’s what you need to know:

1) Preparation Before Installation

- Clear the area – Remove rocks, sharp objects, and debris from berthing walls or slipways to avoid damaging the fender skin.

- Inspect equipment – Check fender skin, end fittings, chains, shackles, and brackets for damage or defects.

- Plan placement – Decide on the number, spacing, and height of fenders based on vessel size, draft, and berthing conditions. Label each fender for future inspection tracking.

2) Common Anchoring Methods

- Through-chain mounting – Chains run through the center or designated holes in the fender, spreading the load evenly. Ideal for larger fenders.

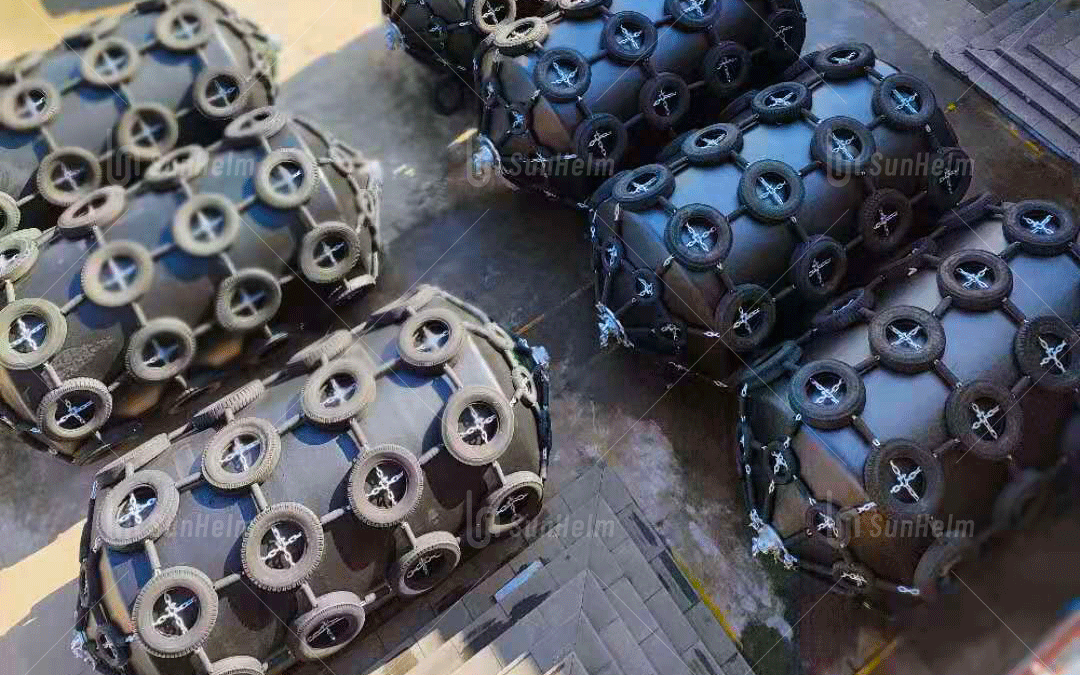

- Tire-net or mesh protection – A net of tires or synthetic mesh around the fender reduces abrasion and adds protection.

- Pad-eye or shackle mounting – Simple to install and widely used; always match shackle strength to the fender’s energy rating.

- Dock frame or skid mounting – For dry docks and shipyards, fenders can rest on brackets or slide rails for better positioning.

Pro tips:

- Use certified chains, shackles, and bolts with proper safety factors.

- Apply even pre-tension on chains to avoid deforming the fender skin.

- Test each fender after installation to ensure stability.

3) Routine Inspection & Care

- Daily checks – Look for cuts, cracks, or abrasion on the skin. Make sure chains and shackles are secure.

- Monthly or quarterly inspections – Examine chain wear, end fittings, and anchoring hardware closely.

- Annual testing – Perform energy absorption checks and, if needed, non-destructive testing for internal damage.

4) Cleaning & Surface Protection

- Rinse fenders regularly with freshwater, especially in saltwater environments.

- Use mild detergents to remove oil stains — avoid harsh solvents that damage the skin.

- Add sacrificial covers or UHMWPE pads in high-wear areas to extend service life.

5) Emergency Repairs

- Small cuts or scratches – Clean the area and patch it using the manufacturer’s repair kit.

- Severe damage – Cover temporarily, remove from service, and arrange for factory repair or replacement.

- Hardware failure – Replace chains or shackles immediately; never operate with faulty connections.

6) Handling & Storage

- Transport carefully – Use wide slings or padded straps to avoid cutting the skin.

- Store properly – Keep fenders in a shaded, dry, and ventilated area away from direct sunlight and chemicals.

- Long-term storage – Rotate fenders periodically to prevent flat spots and uneven stress.

Simple 4-Step Selection Guide

- Define vessel size, berthing speed, and maximum impact energy.

- Calculate required energy absorption (EA) and reaction force.

- Choose diameter, length, and energy rating based on engineering calculations.

- Confirm end fittings and dock structure capacity before finalizing your order.

Quality & Testing Standards

High-quality foam-filled fenders go through strict testing:

- Material tests – Foam compression, recovery rate, and outer skin durability.

- Environmental tests – UV resistance, salt spray testing, and extreme temperature performance.

- Third-party certifications – Independent verification helps ensure long-term reliability.

Frequently Asked Questions (FAQ)

1. Can foam-filled fenders be repaired?

Yes, small cuts can be patched. Severe structural damage may require factory repair or replacement.

2. How long do they last?

With proper care, they can last many years, even under heavy use.

3. Are they suitable for extreme cold or heat?

Yes, but make sure to select skin and foam materials designed for your temperature range.

4. How do I know when to replace them?

Replace when the foam core is exposed, energy absorption drops, or hardware shows serious wear.

5. Do they need constant adjustment after installation?

Not usually, but periodic chain tension checks are recommended.

Final Thoughts

Foam-filled marine fenders are reliable, low-maintenance, and highly effective in protecting both vessels and dock structures. By choosing the right size, installing them properly, and performing routine checks, you can maximize their performance and extend their lifespan.

If you’d like, I can also create a foam-filled fender size chart showing different diameters, lengths, and energy ratings — perfect for helping buyers select the right model quickly.

Do you want me to prepare that size chart next? It would make this article even more useful for buyers.