Marine airbags have revolutionized ship launching and docking. Their secret? Exceptional resistance performance. At Sunhelm, we design airbags that don’t just survive — they perform under pressure, twist, and wear. Let’s dive into the key resistance technologies that set high-quality marine airbags apart.

Why Resistance in Marine Airbags Is a Critical Concern

In real-life ship launching, airbags face extreme conditions — heavy compression, torsion, temperature swings, and abrasive surfaces. Many low-quality airbags fail due to poor resistance performance, causing costly delays or even dangerous blowouts.

Sunhelm once helped a shipyard in Southeast Asia replace substandard airbags after one failed mid-launch. The issue? Weak delamination resistance and poor end-sealing. Our upgraded airbags completed the launch flawlessly — and have been reused over five times since.

That’s why choosing an airbag with superior resistance is not optional — it’s essential.

Featured Snippet: What Makes Marine Airbags So Resistant?

Marine airbags resist failure through multi-layer reinforcement, anti-explosion end fittings, optimized fiber orientation, and durable rubber formulas. These features prevent rupture, delamination, and surface damage—even under extreme pressure.

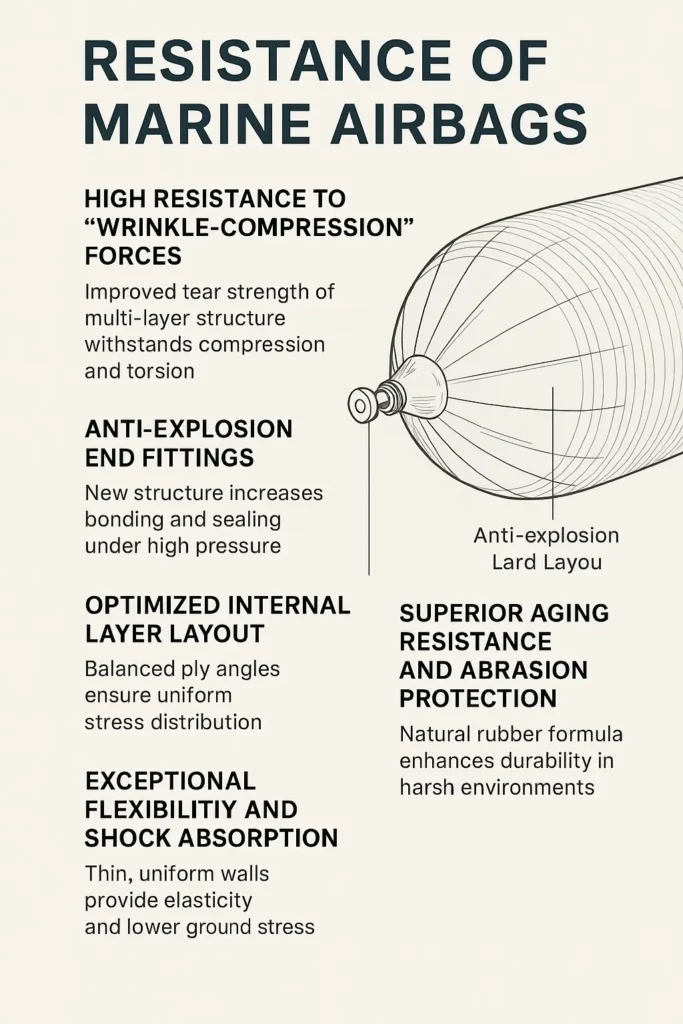

1. High Resistance to “Wrinkle-Compression” Forces

When marine airbags roll under a ship, they face not just vertical compression from the vessel’s weight but also torsion due to uneven movement. This twisting and folding motion — often called “wrinkle-compression” — can lead to:

- Local wall folding

- Stress concentration

- Delamination and fiber fracture

- Sudden burst failure

At Sunhelm, we’ve tackled this with a new-generation rubber formulation and enhanced production techniques, which increase the tear resistance of the fiber-reinforced layers. Our airbags maintain integrity under this harsh dual-force action, dramatically reducing the risk of explosion.

2. Anti-Explosion End Fittings for Safer Pressure Handling

As internal air pressure increases, airbag end fittings become vulnerable to leaks or blowouts — especially after repeated use. Poorly designed end fittings can detach suddenly, posing serious injury risks.

Sunhelm addresses this with a reinforced anti-explosion end structure. Our design improves:

- Bonding strength between rubber body and metal parts

- Sealing capability under high pressure

- Long-term durability even after multiple cycles

To date, Sunhelm airbags using this system have recorded zero leakage incidents.

3. Optimized Internal Layer Layout for Balanced Load Bearing

A marine airbag’s strength lies in its fiber reinforcement layers. But unless those layers are properly arranged, their full strength isn’t used efficiently.

We’ve developed a mathematical strength model to study:

- Main stress magnitude

- Directional changes during rolling and compression

- Optimal fiber orientation

Using this model, we design balanced ply angles, ensuring uniform stress distribution across all layers. Result: our airbags resist rupture even under intense compression.

4. Superior Aging Resistance and Abrasion Protection

Marine airbags operate in brutal environments — saltwater, UV exposure, sand, oil, and chemicals. Sunhelm’s airbags are made with natural rubber bases, carefully formulated for:

- Long-term UV stability

- Seawater and chemical resistance

- Anti-aging durability proven by lab and field tests

- Tough surface wear protection

This ensures that even after extended storage or repeated use, your airbag performs like new.

5. Exceptional Flexibility and Shock Absorption

Unlike rigid structures, Sunhelm’s inflatable rubber airbags are made using a unique continuous winding process and cured at low temperature for a long duration. This results in:

- Uniform wall thickness with no secondary seams

- Thinner and more flexible walls

- Higher elasticity with gentler pressure under hull contact

Such flexibility reduces ground adaptation stress and allows the airbag to absorb shocks more effectively. It adapts perfectly to uneven slipways or slope variations—lowering ship launch risks significantly.

FAQ – Marine Airbags

What causes marine airbag failure?

Failures often result from delamination, end fitting blowouts, UV degradation, or structural weakness under compression and torsion.

How long do high-quality marine airbags last?

With proper design and care, they can last 5–10 full launch cycles.

What pressure can a marine airbag withstand?

It depends on the size and model, but many Sunhelm airbags can handle up to 0.5 bar working pressure, with burst pressure three times higher.

Can airbags be reused after one launch?

Yes—especially Sunhelm’s reinforced models. Many clients report safe use for multiple launches with minimal wear.

Final Thoughts: Resistance Means Reliability

Marine airbag resistance isn’t just a technical metric — it’s the difference between a smooth launch and a catastrophic failure. At Sunhelm, we’re proud to engineer airbags that meet today’s highest standards in anti-compression, anti-aging, and anti-blowout safety.