When ports and offshore facilities face big waves, freezing temperatures, or salty water, they need fenders they can rely on. That’s where foam fenders come in. Unlike inflatable types that can pop or leak, foam fenders from Sunhelm are solid, unsinkable, and built for the toughest conditions.

Let’s explore why foam fenders perform so well in harsh marine environments—and why more shipyards, terminals, and offshore operators are choosing them.

What Makes Foam Fenders So Stable?

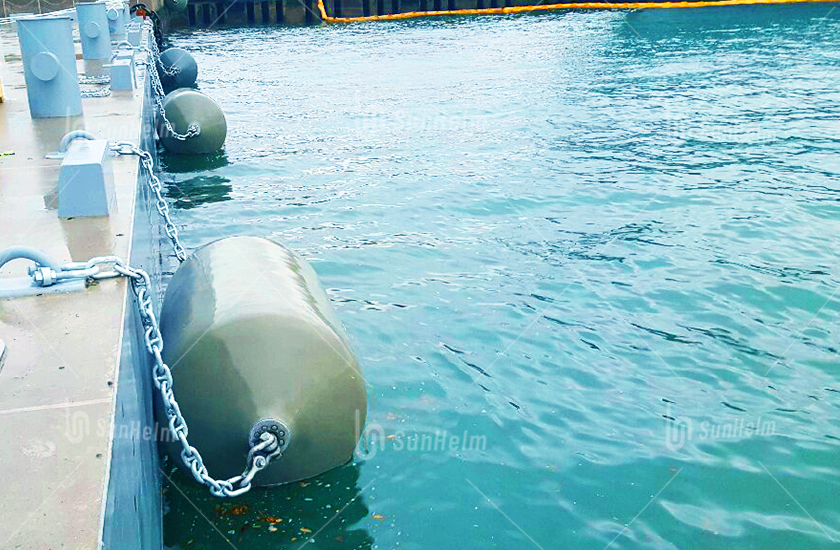

Foam fenders, also called foam-filled fenders, use closed-cell polyethylene foam as the core and are wrapped with a durable polyurethane (PU) skin. The foam inside doesn’t absorb water, and even if the skin gets damaged, the fender keeps working.

Key Benefits:

- No air = no leaks or bursts

- High energy absorption with low reaction force

- Won’t sink, even if punctured

- UV, saltwater, and temperature resistant

- Minimal maintenance, long service life (10–25 years)

Performance in Rough Sea Conditions

Sunhelm foam fenders are designed to handle aggressive berthing forces and open sea waves.

- Built to compress up to 60% while absorbing strong impact energy

- Spread the force across a large area to reduce damage to the ship hull

- No inflation needed, which eliminates the risk of sudden failure

- Used for STS (ship-to-ship) transfers, oil terminals, and exposed docks

Foam fenders are naturally buoyant and stable, even in rolling seas. Their flexible structure makes them much safer and more reliable than air-filled fenders in rough conditions.

Arctic-Ready: Cold Zone Durability

Cold weather is no problem for foam fenders. In fact, lower temperatures often make them even stronger.

- Foam becomes firmer in the cold, which helps absorb energy better

- PU skin stays flexible, even in sub-zero temperatures

- No metal corrosion, since the foam core doesn’t contain any metal parts

- Used in Arctic naval bases, ice-prone terminals, and frozen rivers

Several ports in Northern Europe and Canada already use foam fenders year-round in snow and ice. Sunhelm products are field-tested for performance below -30°C.

Resistant to Salty Water and Marine Corrosion

Salt is one of the toughest elements for marine gear—but foam fenders resist it naturally.

- The PU skin resists salt spray, UV rays, oil, and chemicals

- No rust, no water absorption, and no pressure loss

- The surface won’t mark or scratch vessel hulls, even on white-painted ships

- Works well in coastal terminals, military bases, and container ports

Our fenders are trusted by operators in tropical salt-heavy zones and offshore platforms, where regular fenders would fail fast.

Tested to Meet Global Standards

Sunhelm foam fenders follow strict international quality guidelines:

- PIANC WG211 energy and reaction force standards

- Lab-tested for salt spray, compression fatigue, and aging

- Tested from -40°C to +50°C to ensure year-round durability

This testing helps guarantee long-term performance and keeps vessels protected under real-world conditions.

Real Use Cases and Product Types

| Use Case | Foam Fender Type | Why It Works |

|---|---|---|

| Open-sea STS transfers | Heavy-duty chain‑net foam fenders | Extra tough, handles high impact energy |

| Arctic or ice docks | Submarine-grade foam fenders | Cold-proof, ice-resistant, always floating |

| High-traffic container terminals | Standard floating foam fenders | Durable, low reaction force, no leaks |

Whether you need fenders for small fishing boats or oil tankers, Sunhelm offers a range of foam fender types to suit your needs.

Choosing the Right Foam Fender

When selecting foam fenders, consider these factors:

- Wave height and sea conditions

- Ship size and docking energy

- Temperature range

- Need for chain-net protection

High-density foam works best for heavy berthing forces. Smaller vessels or calm waters can use lower-density foam for lighter touch.

If your site has ice, waves, or heavy salt spray, foam fenders will always be the safer choice over inflatable or solid rubber types.

Easy Maintenance = Lower Long-Term Cost

Foam fenders from Sunhelm are designed for low upkeep:

- No inflation checks needed

- No metal inside = no rust

- Just inspect outer skin and lifting hardware once a year

- Replace damaged skin or fittings easily

With proper care, most foam fenders last over a decade without major repairs.

FAQ

Q1: Do foam fenders absorb water if they get punctured?

No. The foam is closed-cell, so it never soaks up water or sinks.

Q2: Will foam fenders crack in freezing temperatures?

Not at all. The foam gets firmer, which improves performance in the cold.

Q3: Are they better than pneumatic fenders?

For extreme environments, yes. Foam fenders don’t burst, require less maintenance, and handle salt and cold better.

Q4: How often should I inspect them?

Once a year is enough in most ports. Just check the skin, lifting eyes, and chains.

Final Thoughts: Why Sunhelm Foam Fenders Are Built for the Extreme

From high seas to frozen docks, Sunhelm foam fenders prove their strength, stability, and value every day. Whether you’re operating in tropical storms or icy waters, our fenders are built to perform—no leaks, no sinking, no surprises.

If your terminal, yard, or offshore facility needs tough and reliable protection, foam fenders are the way to go.

👉 Contact Sunhelm today for sizing charts, testing data, or a free quote tailored to your environment.