Introduction

Boat foam fenders are key to protecting vessels and docks. They help absorb impact when boats dock, preventing damage to both sides. Compared to other types of fenders, foam-filled ones offer great durability and require little maintenance. But what exactly is inside them?

1. What’s Inside a Foam-Filled Fender?

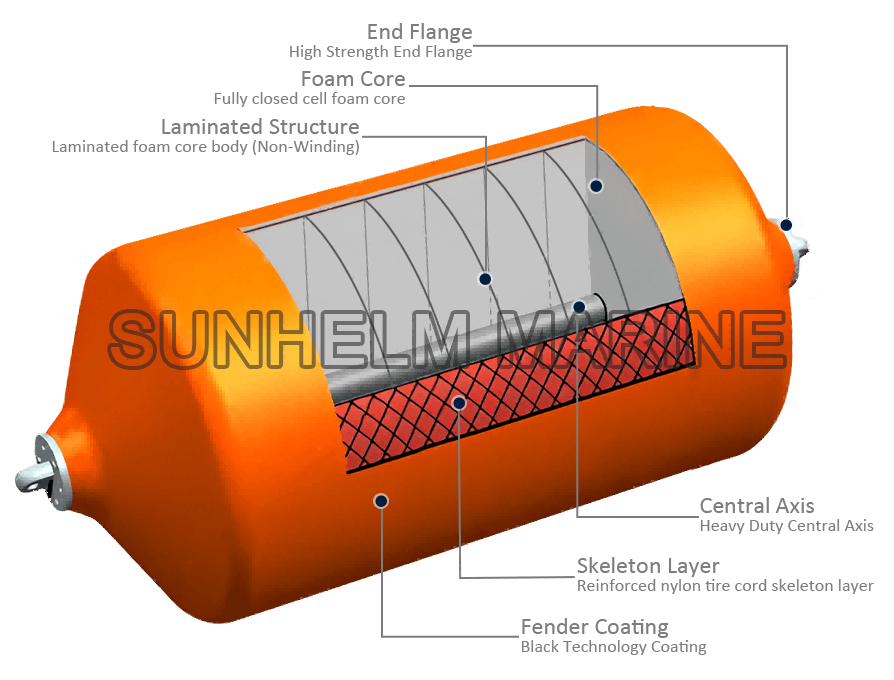

Foam-filled boat fenders contain closed-cell foam at their core. This foam is often made from EVA (ethylene-vinyl acetate) or PE (polyethylene). Both materials are lightweight, highly buoyant, and do not absorb water.

Unlike inflatable fenders, these fenders don’t rely on air pressure. Even if the outer skin gets damaged, the foam inside keeps the fender floating and functional. That makes them ideal for tough marine environments and long-term use.

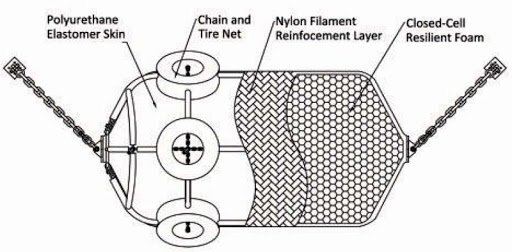

Some designs include an inner steel structure or reinforced chain system to improve strength and stability—especially for larger ships and heavy-duty mooring.

2. The Outer Construction

The core foam is wrapped in a layer of strong filament reinforcement, such as nylon mesh or canvas. This gives the fender extra strength and helps it hold its shape. Over that layer, manufacturers apply a thick coating of polyurethane (PU) or polyurea, which forms a smooth, durable outer skin.

This protective skin is resistant to UV rays, saltwater, and rough contact with docks or hulls. It’s tough enough to withstand years of daily use, even in busy ports.

Many foam-filled marine fenders also come with outer rope nets or recycled tires. These extras protect the outer layer and add grip during contact, reducing wear and tear on both the fender and the vessel.

3. Why Use Closed-Cell EVA or PE Foam?

The use of closed-cell EVA foam or PE foam gives these fenders some major advantages:

- No water absorption: Closed-cell foam keeps water out, ensuring the fender stays light and buoyant.

- Excellent energy absorption: The foam spreads out impact energy, reducing the force on boats and docks.

- No inflation needed: There’s no risk of air leaks, and no need for pumps or pressure checks.

- Long lifespan: These fenders last for years, even with little maintenance.

Compared to traditional rubber fenders or pneumatic models, foam-filled boat fenders provide more consistent performance, especially in extreme weather.

4. EVA Foam vs. PE Foam

EVA foam is soft, flexible, and known for its shock-absorbing ability. It performs well in cold environments and resists cracking under pressure. This makes it great for applications where flexibility matters.

PE foam, on the other hand, is denser and more rigid. It’s a better choice for high-impact zones or large vessels that need maximum resistance and structure. Both foam types work well for marine fenders, depending on your use case.

Whether you use an EVA foam marine fender or a PE foam fender, both options offer excellent energy absorption and long-lasting buoyancy.

5. Common Applications

Foam-filled fenders are used in many settings:

- Commercial ports and terminals

- Naval bases and large shipyards

- Offshore platforms

- Yachts, ferries, and tugboats

They are perfect for ship-to-ship transfers, docking at rough piers, and mooring in tidal conditions. Thanks to their design, foam-filled fenders can handle all kinds of contact without losing shape or performance.

Many companies choose these fenders because of their low maintenance, reliable floatation, and ability to perform even after years of use.

6. Installation and Maintenance Tips

Installing foam-filled fenders is simple. They can be hung with strong chains or ropes, and many models include tire nets or rope covers for extra durability.

Routine care is easy:

- Inspect the outer skin for cuts or wear

- Replace the netting if it becomes damaged

- If needed, re-skin the outer layer without replacing the whole fender

With proper care, a good foam-filled boat fender can last 10 years or more.

Conclusion

Boat foam fenders are filled with closed-cell EVA or PE foam, wrapped in a tough skin and reinforced with fiber mesh or chains. This makes them ideal for high-impact, high-traffic marine environments.

They float, absorb energy, and keep working even if damaged. Whether you manage a busy dock or operate ships at sea, choosing a foam-filled marine fender ensures safety, durability, and peace of mind.