When it comes to protecting ports, terminals, and vessels during berthing operations, the cell fender system is one of the most reliable and widely used solutions in the maritime industry. Known for its high energy absorption and low reaction force, a properly designed cell fender system ensures safe berthing for vessels of all sizes while reducing the risk of structural damage.

In this guide, we’ll explain what a cell fender is, how it works, and how to select the right system for your port or terminal.

What Is a Cell Fender?

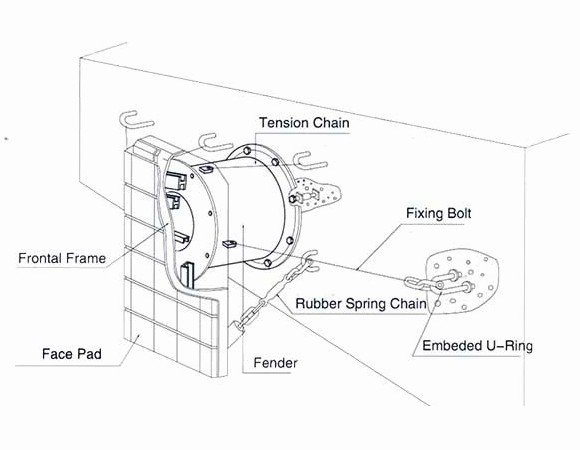

A cell fender is a type of high-performance fixed fender system designed to absorb the kinetic energy generated during vessel berthing. It consists of a hollow cylindrical rubber body combined with a steel frontal panel that distributes impact forces evenly across the ship’s hull.

Key advantages of cell fenders:

- High energy absorption — suitable for large vessels and high-traffic berths

- Low reaction force — protects both the vessel and the quay structure

- Durability — excellent resistance to UV, saltwater, and harsh environments

- Long service life — typically more than 10 years with proper maintenance

How a Cell Fender Works and How to Select the Right One

The working principle of a cell fender and its selection process are closely related, so we’ll cover them together.

1. How Cell Fenders Absorb Energy

When a vessel makes contact with the berth, the frontal panel presses against the ship’s hull and transfers the load to the rubber body:

- Elastic deformation — the hollow rubber body compresses, storing kinetic energy.

- Energy dissipation — part of the energy is converted into heat, reducing the impact transmitted to the quay.

- Even force distribution — the large steel frontal panel ensures the pressure on the vessel’s hull stays low, preventing local damage.

This mechanism allows cell fenders to handle high berthing energies while keeping reaction forces low, making them ideal for heavy-duty applications.

2. Key Performance Parameters

Before selecting a cell fender, it’s essential to understand its technical specifications:

| Parameter | Definition | Unit |

|---|---|---|

| Energy absorption | The maximum energy the fender can absorb per berthing | kJ |

| Reaction force | The force exerted back on the quay at maximum compression | kN |

| Deflection | Fender deformation at full load | mm |

| Hull pressure | Average surface pressure on the ship hull | kN/m² |

| Service life | Expected lifespan under normal conditions | Years |

3. Steps for Selecting the Right Cell Fender

Step 1. Calculate Berthing Energy

According to PIANC’s Guidelines for the Design of Fender Systems (MarCom WG33, 2002), berthing energy is commonly calculated as:

E = 1/2 × M × v^2 × C

Where:

- m = vessel displacement (ton)

- v = berthing velocity (m/s)

- C = energy coefficient (accounts for tidal conditions, mooring type, etc.)

Step 2. Determine Allowable Reaction Force

The vessel’s hull can only handle limited surface pressure. Ensure the fender’s maximum reaction force doesn’t exceed the hull’s structural tolerance.

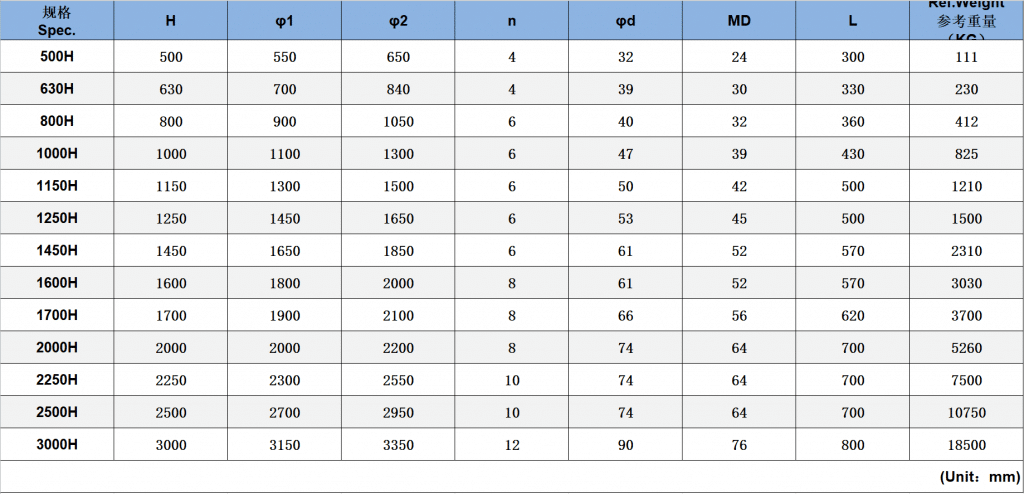

Step 3. Choose the Suitable Fender Model

Use the manufacturer’s performance table to select a model where:

- Energy absorption ≥ calculated berthing energy

- Reaction force ≤ allowable hull pressure

- Deflection within acceptable limits to prevent overstressing the fender

Step 4. Check Safety Factors

Always account for extreme conditions, such as strong winds or higher-than-expected approach speeds. A safety factor of 1.25–1.5 is commonly recommended.

4. Common Selection Mistakes to Avoid

- Focusing only on energy absorption — ignoring reaction forces may lead to hull damage.

- Choosing an undersized frontal panel — small panels increase local hull pressure.

- Overlooking installation constraints — quay structure compatibility is critical.

- Skipping safety factor checks — extreme conditions can overload undersized fenders.

Installation and Maintenance Tips

1. Installation Best Practices

- Secure anchoring — match the backing panel to quay structure strength.

- Precise alignment — keep the fender perfectly vertical and flush with the quay.

- Anti-corrosion protection — coat bolts, backing plates, and steel parts in marine environments.

2. Routine Maintenance

- Monthly inspections — check for surface cracks or cuts.

- Quarterly checks — verify the recovery performance after compression.

- Annual testing — inspect bolt torque, frontal panel integrity, and rubber aging.

With proper care, a high-quality cell fender can last 10–15 years or more.

Typical Applications

Cell fenders are used in a wide range of scenarios:

- Container terminals — for frequent berthing of large vessels

- Oil & LNG jetties — where safety and reliability are critical

- Shipyards and dry docks — suitable for diverse vessel sizes

- Heavy-duty berths — ideal for tankers, bulk carriers, and other large ships

FAQ: Common Questions About Cell Fenders

1. How long does a cell fender last?

With regular inspections, a cell fender can typically last 10–15 years.

2. Are cell fenders suitable for all vessel sizes?

They’re ideal for medium to large vessels, but for small boats or temporary berthing, pneumatic or foam fenders may be better.

3. How do I know when to replace a cell fender?

If you notice deep cracks, permanent deformation, or a 20% drop in energy absorption capacity, it’s time to replace it.

4. What preparation is needed before installation?

Check the quay structure’s strength, prepare lifting equipment, and ensure proper corrosion protection for steel components.

Conclusion

A cell fender system offers one of the most effective and durable solutions for protecting both vessels and quay structures during berthing. By understanding its working principles and following a proper selection process, you can ensure maximum safety, efficiency, and cost-effectiveness for your port operations.

If you need detailed specifications, performance charts, or a customized cell fender solution, feel free to contact Sunhelmmarine engineering team — we’ll help you choose the best fit for your application.