In modern ports and ship operations, the demand for reliable fendering solutions has never been greater. Sling type pneumatic rubber fenders are one of the most flexible and cost-effective options for protecting both vessels and berthing structures from impact damage. At Sunhelmmarine, we design and manufacture high-performance sling type fenders tailored for real-world marine environments where safety, efficiency, and durability matter most.

Key Features and Technical Performance

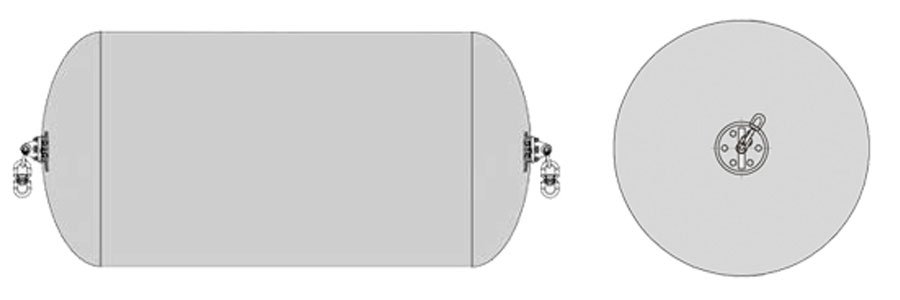

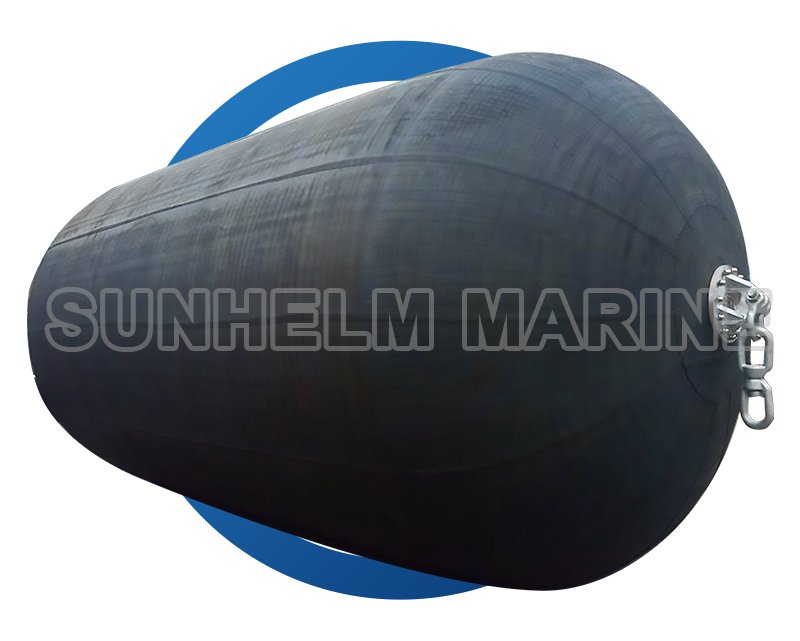

Sling type pneumatic fenders are made of high-strength synthetic-tire-cord layers and rubber layers that form a pressurized air chamber. This chamber absorbs kinetic energy when vessels make contact with the dock or another ship.

What makes the sling type design unique is its reinforced strap (sling) system that replaces the traditional chain-net cover. This reduces weight, simplifies handling, and provides better flexibility for temporary or mobile berthing operations.

Typical features include:

- High energy absorption with low reaction force, ensuring maximum hull protection.

- Lightweight and easy installation, no heavy chain net or tire cover required.

- Excellent durability, resistant to abrasion, UV, and seawater corrosion.

- Wide pressure range, available in 50 kPa and 80 kPa types to suit various vessel sizes.

- Flexible mounting options, suitable for different berthing angles and mooring systems.

At Sunhelmmarine, every fender is tested for air tightness, burst pressure, and dimensional tolerance before delivery. Optional accessories include shackles, lifting belts, valves, and repair kits.

Main Application Areas

1. Commercial Ports and Container Terminals

Sling type pneumatic rubber fenders are widely used for container ships and general cargo vessels. Their soft contact and strong energy absorption protect both the quay wall and vessel hull during frequent berthing.

Because of their lightweight structure, these fenders are easy to move or adjust along the dock, allowing flexible berth allocation in busy terminals.

2. Bulk Cargo and Mining Wharves

In heavy-duty operations such as ore or coal loading, sling type fenders provide excellent protection against high-energy impacts from bulk carriers. Their slings allow angled contact without slipping, which reduces localized stress on the dock structure.

They are also ideal for long-duration mooring, where the vessel remains alongside for extended loading cycles.

3. LNG and Chemical Terminals

Safety is critical for LNG, LPG, and chemical handling berths. Sling type pneumatic fenders are non-sparking and have a low reaction force, reducing the risk of structural damage or fuel vapor ignition.

Sunhelmmarine can supply models compatible with Yokohama specifications and can customize fenders with flame-retardant or low-temperature materials upon request.

4. Passenger and Ferry Docks

Passenger terminals require smooth berthing and minimal vibration. Sling type fenders ensure low impact even when smaller vessels dock at high frequency. They improve comfort for passengers and reduce wear on both the dock and vessel sides.

5. Offshore Projects and Temporary Mooring

For offshore construction vessels, floating platforms, and heavy-lift operations, sling type pneumatic rubber fenders are easy to deploy, retrieve, and store. Their mobility makes them perfect for emergency berthing, ship-to-ship (STS) transfer, and temporary mooring points.

6. Special Applications

Sunhelmmarine’s engineering team also supports custom projects such as oversized vessels, oblique berthing angles, and extreme-climate ports. Our fenders can be produced up to 4,500 mm in diameter and 12,000 mm in length, ensuring coverage for the largest vessels in operation.

Design and Installation Guidelines

To maximize performance, proper design and installation are essential:

- Energy calculation – match fender energy absorption (EA) to vessel displacement and berthing velocity.

- Compression ratio – maintain 60% deflection for rated energy absorption.

- Installation spacing – ensure even distribution along the quay wall.

- Inflation pressure – verify at 50 kPa or 80 kPa depending on specification.

- Inspection – check surface wear, sling tension, and valve condition regularly.

Routine maintenance only requires periodic air-pressure checks and visual inspections. If the fender surface is scratched or abraded, Sunhelmmarine provides simple repair kits and technical guidance for on-site patching.

Cost Efficiency and Long-Term Value

Although initial investment in sling type pneumatic rubber fenders may be higher than rigid fenders, their lifespan, low maintenance, and superior energy performance result in lower total cost of ownership.

They effectively reduce hull damage, downtime, and repair costs. The lightweight design means easier handling and relocation without cranes, saving time during port operations.

For ports with mixed vessel traffic, the same set of sling type fenders can serve multiple berths, making them an efficient and versatile asset.

Why Choose Sunhelmmarine

Sunhelmmarine is a factory-direct manufacturer specializing in marine fendering systems and ship-launching equipment. With years of experience in pneumatic rubber fender production, we deliver:

- Certified materials and strict quality inspection before shipment.

- Custom designs for diameter, length, pressure, and sling configuration.

- Fast delivery and technical support worldwide.

- Full after-sales service including repair kits, spare parts, and installation guidance.

Whether you need a single fender for ship-to-ship operations or a complete dock protection system, Sunhelmmarine can design a solution that fits your exact requirements.

Real-World Applications

Case 1: Container Port Expansion, Southeast Asia

Sunhelmmarine supplied 32 units of sling type pneumatic rubber fenders (3.0 m × 6.0 m, 80 kPa) for a new deep-water terminal. The project achieved a 25% reduction in hull contact force compared with conventional chain-net types.

Case 2: Offshore Construction Vessel Support, Middle East

Lightweight sling fenders enabled quick deployment and recovery during floating crane operations, reducing downtime and improving vessel safety in open-sea conditions.

FAQ

Q1: What vessel sizes can sling type fenders handle?

A: They can serve vessels from 500 DWT barges up to 300,000 DWT VLCCs depending on fender size and pressure.

Q2: How often should they be maintained?

A: Check air pressure monthly and surface condition quarterly. Properly maintained fenders can last over 10 years.

Q3: Can they be used in cold or tropical climates?

A: Yes. Sunhelmmarine uses weather-resistant rubber compounds suitable for temperatures from –40 °C to +60 °C.

Q4: Are they compatible with Yokohama-type fittings?

A: Absolutely. Our sling type pneumatic rubber fenders can be supplied with the same valve and flange configuration for direct replacement.

Q5: What is the normal delivery time?

A: Standard sizes are usually delivered within 4–6 weeks; custom orders depend on design complexity and quantity.

Q6: Do you provide installation support?

A: Yes, we offer technical drawings, manuals, and online or on-site guidance for installation and inflation.

Contact Sunhelmmarine

Looking for reliable sling type pneumatic rubber fenders for your next port or ship project?

Contact Sunhelmmarine today for free selection advice and a detailed quotation.

Email: info@sunhelmmarine.com | Website: www.sunhelmmarine.com