When it comes to LNG (Liquefied Natural Gas) terminals, choosing the right fender system is not just a technical decision—it’s a matter of safety, performance, and long-term cost efficiency. At Sunhelm, we often receive the question:

“Are cone fenders suitable for LNG docks?”

The short answer: Yes—when designed and configured correctly, cone fenders are one of the best solutions for LNG berths.

Here’s why.

1. The Challenges of LNG Berthing

LNG carriers are among the largest ships in operation, often measuring over 300 meters and carrying highly sensitive cargo. Berthing them safely comes with unique challenges:

- High berthing energy due to vessel size and momentum

- Strict safety requirements – anti-static, spark prevention, and flame resistance

- Low hull pressure limits – LNG carriers often have thinner hull plating compared to oil tankers

- Tidal variations and angled berthing – affecting fender alignment and contact area

- Low-temperature conditions – materials must perform even in extreme cold

Any fender system at LNG docks must address these conditions without compromising safety or efficiency.

2. What Are Cone Fenders?

Cone fenders are a type of fixed rubber fender with a conical body shape. This design allows for:

- High energy absorption at relatively low reaction forces

- Large deflection capacity, meaning they can handle more berthing angles without losing performance

- Stable performance under compression, even in difficult berthing conditions

Typically, cone fenders are used with large fender panels covered in UHMW-PE (ultra-high molecular weight polyethylene) pads, which reduce friction and protect the ship’s hull coating.

3. Why Cone Fenders Are Ideal for LNG Docks

From Sunhelm’s experience in supplying fender systems worldwide, cone fenders offer multiple advantages for LNG berths:

3.1 High Energy Absorption with Low Reaction Force

LNG carriers require fenders that can absorb large amounts of energy without exerting high pressure on the hull. Cone fenders achieve this balance, ensuring vessel and berth safety.

3.2 Uniform Hull Pressure

When paired with a large steel fender panel and UHMW-PE face pads, cone fenders spread the load evenly across the hull. This prevents local damage and meets hull pressure limits set by LNG ship operators.

3.3 Tolerance to Angled and Eccentric Berthing

Cone fenders maintain performance even when ships berth at angles or with tidal offsets—a common scenario in LNG docks.

3.4 Long Service Life

With proper material selection (low-temperature resistant rubber compounds and corrosion-protected steel parts), cone fenders can last decades, reducing total lifecycle cost.

4. LNG-Specific Design Considerations

For cone fenders to perform safely at LNG docks, certain design factors are essential:

- Low-temperature rubber compound: Maintains flexibility and strength even in extreme cold.

- Anti-static & spark prevention: UHMW-PE pads can be formulated to prevent static buildup.

- Corrosion protection: Hot-dip galvanized or stainless steel fittings for long-term durability.

- Correct sizing: Based on berthing energy calculations for the specific LNG carrier fleet.

- Compliance with PIANC guidelines: Internationally recognized design and testing standards.

At Sunhelm, we perform detailed engineering calculations for each LNG project to ensure every cone fender meets these requirements.

5. Cone Fenders vs. Other Fender Types for LNG Use

| Fender Type | Energy Absorption | Hull Pressure | Angled Berthing | Maintenance | Common Use Cases |

|---|---|---|---|---|---|

| Cone Fenders | High | Low | Excellent | Low | LNG, oil terminals, bulk ports |

| Cell Fenders | Moderate | Moderate | Good | Low | General cargo berths |

| Foam-Filled | Low–Moderate | Variable | Excellent | Medium | Temporary berths, mooring buoys |

Cone fender stand out for LNG docks due to their unique balance of high performance, safety, and adaptability.

6. Installation and Maintenance Tips

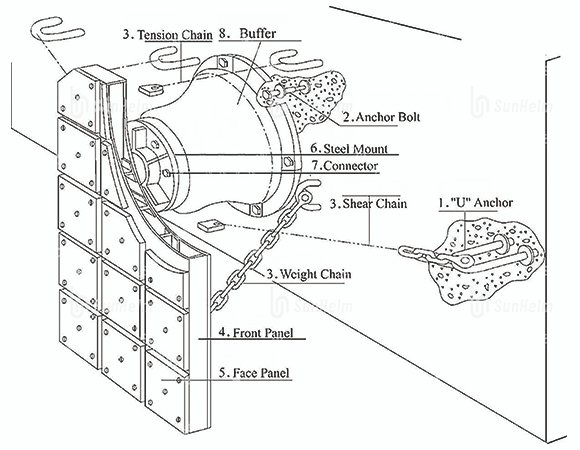

- Anchor system: Ensure concrete strength and bolt placement match design loads.

- Panel inspection: Check UHMW-PE pads for wear or damage regularly.

- Bolt torque check: Retighten according to the manufacturer’s schedule.

- Anti-static system: Test grounding continuity during routine inspections.

- Cold-weather inspection: Look for surface cracks or stiffening in extreme low temperatures.

7. Common Mistakes to Avoid

- Ignoring hull pressure limits – can lead to coating damage or deformation.

- Skipping low-temperature testing – regular rubber may fail in LNG climates.

- Underestimating berthing angle effects – leads to uneven load distribution.

- Poor panel sizing – too small a panel increases local pressure.

8. Sunhelm’s LNG Fender Projects

Sunhelm has supplied cone fenders for LNG terminals in Asia, the Middle East, and Europe.

- Case 1: Upgraded from cell fenders to cone fenders, reducing hull pressure by 20% and extending maintenance intervals.

- Case 2: Custom low-temperature rubber for Arctic LNG terminal, operating reliably at -45°C.

9. FAQ

Q: How do cone fenders protect the ship’s hull?

By using large panels with UHMW-PE pads to spread the load and reduce friction.

Q: How long do cone fender last?

With proper materials and maintenance, 20–25 years or more.

Q: Do they require special installation?

Yes—anchor layout, panel size, and grounding systems must be designed for LNG use.

10. Conclusion – Why Choose Sunhelm Cone Fenders

If your LNG berth requires high energy absorption, low hull pressure, and reliable performance in all conditions, cone fenders are one of the best solutions available.

At Sunhelm, we design, manufacture, and supply LNG-ready cone fender with full engineering support—from berthing energy calculations to on-site installation guidance.

Contact us today to get a custom cone fender solution for your LNG terminal.