Foam filled fenders are one of the most durable and low-maintenance fender systems used in modern ports and offshore facilities. At Sunhelmmarine, we manufacture high-performance foam filled fenders with advanced materials and strict quality control to ensure maximum protection and service life.

Our products are available in both netless and net-type designs to meet diverse marine engineering requirements.

Foam Filled Fender Overview

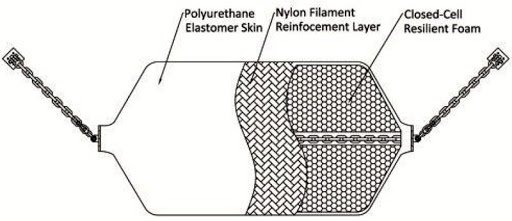

Foam filled fenders consist of an energy-absorbing closed-cell foam core, a tough polyurethane outer skin, and a reinforced internal structure. This unique combination allows the fender to provide excellent energy absorption with low reaction force, even after repeated impacts.

The closed-cell foam ensures the foam fender remains unsinkable even if the skin is damaged, while the PU layer offers strong resistance to oil, seawater, and UV exposure. These advantages make them ideal for ship-to-ship (STS), ship-to-dock (STD), and offshore applications.

Advantages of Sunhelmmarine Foam Filled Fenders

- High energy absorption with stable reaction performance

- Unsinkable foam core for continuous operation even when damaged

- Strong polyurethane skin resistant to wear, oil, and seawater

- Custom sizes and foam densities for different vessel types

- Available with or without tire net protection

- Simple installation and minimal maintenance

- Long service life and cost efficiency

Netless Foam Filled Fenders

The netless type foam filled fenders are widely used in commercial ports, fishing terminals, and medium-size vessel berthing. They feature a smooth polyurethane skin, providing low friction during contact and requiring no external protection.

Typical Applications:

Cargo terminals, fishing ports, STS operations, yacht marinas.

Technical Specification — Netless Type

| Fender Size (D×L mm) | Capacity | Energy Absorption (kNm) | Reaction Force (kN) | Pressure (kN/m²) |

|---|---|---|---|---|

| 500×1000 | Low | 6 | 38 | 104 |

| 700×1500 | Standard | 28 | 136 | 172 |

| 1000×2000 | High | 90 | 311 | 224 |

| 1500×3000 | High | 304 | 701 | 224 |

| 2000×3500 | High | 601 | 1048 | 224 |

| 2500×5500 | High | 1592 | 2194 | 224 |

| 3300×6500 | High | 3170 | 3326 | 224 |

| (Intermediate sizes available upon request) |

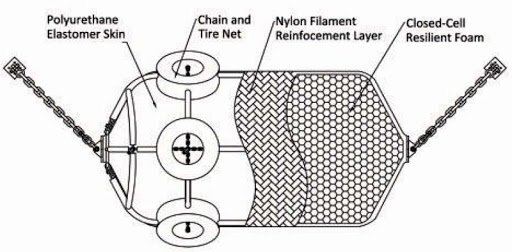

Net-Type Foam Filled Fenders

The net-type foam filled fenders are equipped with a heavy-duty tire and chain net for additional protection. This type is ideal for large vessels, naval bases, and offshore terminals where higher impact resistance and durability are required.

The tire net minimizes surface damage, extending the fender’s lifespan even under extreme conditions.

Typical Applications:

LNG terminals, naval ports, oil platforms, offshore supply bases.

Technical Specification — Net-Type

| Fender Size (D×L mm) | Capacity | Energy Absorption (kNm) | Reaction Force (kN) | Pressure (kN/m²) |

|---|---|---|---|---|

| 500×1000 | Low | 6 | 38 | 104 |

| 700×1500 | Standard | 28 | 136 | 172 |

| 1000×2000 | High | 90 | 311 | 224 |

| 1500×3000 | High | 304 | 701 | 224 |

| 2000×3500 | High | 601 | 1048 | 224 |

| 2500×5500 | High | 1592 | 2194 | 224 |

| 3300×6500 | High | 3170 | 3326 | 224 |

| (Customized sizes and foam densities available) |

Applications

- Port and harbor terminals

- Ship-to-ship (STS) transfer operations

- Oil and gas terminals

- Naval bases

- Offshore platforms and floating docks

Sunhelmmarine foam filled fenders have proven performance in hundreds of global installations, providing safe and reliable berthing protection for various vessel types.

Why Choose Sunhelmmarine

Sunhelmmarine is a professional manufacturer of marine fenders with years of production experience and an excellent reputation in global projects. Our products are made in-house, ensuring consistent quality, competitive pricing, and customizable design.

We provide:

- Factory-direct supply with short delivery time

- Optional colors, logos, and accessories

- Detailed test reports and quality certification

- Expert technical support for project design

Choosing Sunhelmmarine means choosing long-term value and trusted performance in every fender.

FAQ

Foam filled fenders have a foam core inside a durable outer layer. They absorb impact energy, reducing force on your vessel and dock during berthing or ship-to-ship transfers.

Foam filled fenders require no air pressure, reducing maintenance. They’re unsinkable, durable, and perform well in different weather conditions.

Yes, we offer custom sizes and energy levels to match your vessel’s needs and the docking environment.

No, they are low-maintenance. Regular inspection and cleaning are all that’s needed to keep them in good condition.

Yes, we provide full installation support to ensure your fenders are properly set up and perform optimally.

Contact Us

Looking for foam filled fenders for sale with proven quality and fast delivery?

Get in touch with Sunhelmmarine today for a quotation or project consultation — our team will help you find the best fender solution for your port or vessel.