Introduction

In modern port construction, offshore terminals, and ship berthing operations, marine rubber fenders play a crucial role in protecting both vessels and dock structures. They absorb massive berthing energy and minimize structural damage during mooring.

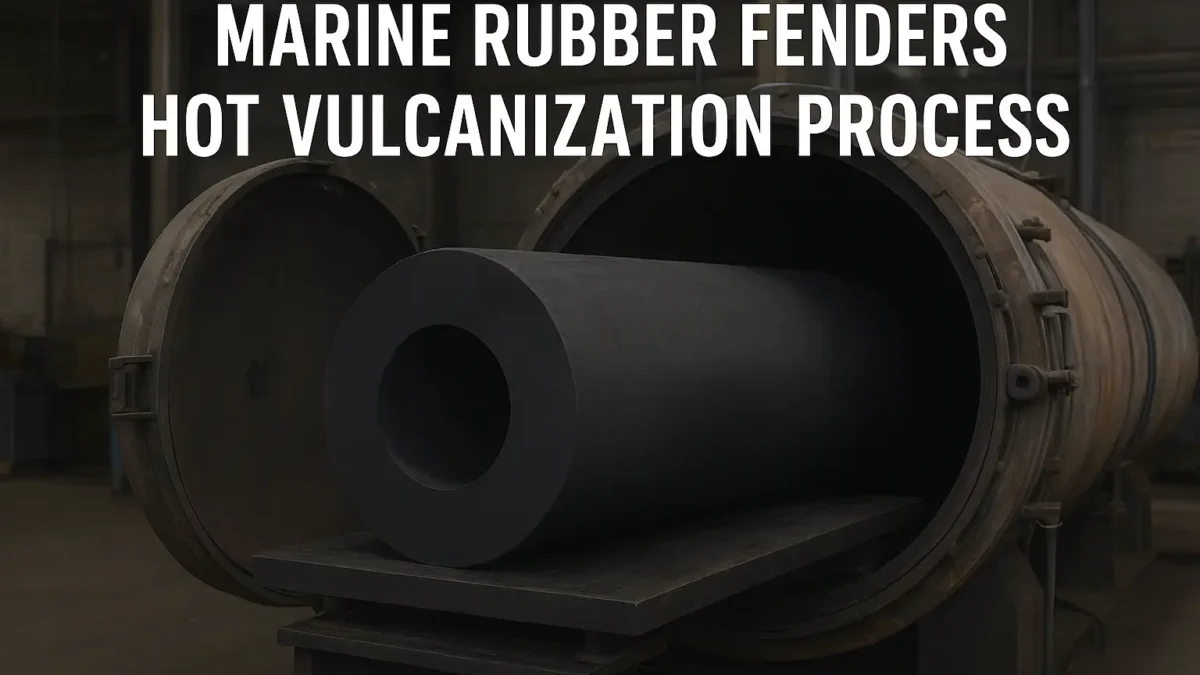

However, to ensure these rubber fenders perform reliably for years, one critical process makes the difference — hot vulcanization. This advanced curing technology significantly improves the durability, elasticity, and energy absorption capacity of marine rubbers, making them suitable for the harsh marine environment.

In this article, we will explore what hot vulcanization is, why it matters, how the process works, and how it impacts the overall quality of marine rubber fenders.

What Is Hot Vulcanization and Why It Matters

Hot vulcanization is a manufacturing process in which raw rubber undergoes a cross-linking reaction under controlled heat and pressure. By introducing sulfur or peroxide-based curing systems, rubber molecules bond to form a three-dimensional network structure.

Benefits of Vulcanization

Without vulcanization, rubber fenders would remain soft, sticky, and prone to damage. Hot vulcanization offers several advantages:

- Enhanced elasticity and shape recovery – prevents permanent deformation under heavy loads.

- Higher wear and tear resistance – extends lifespan in high-friction marine conditions.

- Improved weather and ozone resistance – protects against UV radiation, salt spray, and ozone degradation.

- Superior energy absorption – ensures optimal performance during ship berthing.

- Stronger adhesion to internal steel frames – guarantees stable bonding between rubber and metal parts.

In short, vulcanization transforms raw rubber into a high-performance material capable of withstanding the extreme demands placed on marine rubber fenders.

Material Selection and Compound Design

The performance of marine rubbers heavily depends on material formulation. A well-balanced compound ensures superior flexibility, durability, and impact absorption.

- Base Rubber: Natural Rubber (NR) for high elasticity; Styrene-Butadiene Rubber (SBR) for better abrasion resistance; EPDM for enhanced weathering resistance.

- Reinforcing Agents: High-structure carbon black improves tensile strength and tear resistance.

- Anti-Aging Additives: Antioxidants, anti-ozone wax, and stabilizers prolong lifespan.

- Curing System: A precise balance of sulfur, accelerators, and activators ensures controlled vulcanization.

- Bonding Agents: Special adhesives enhance the bonding strength between rubber layers and embedded steel components.

Key Equipment and Workflow

Core Equipment

- Mixing Machines: Banbury mixers and two-roll mills ensure uniform compound dispersion.

- Forming Machines: Extruders, calenders, and molding presses shape semi-finished parts.

- Vulcanization Systems: Steam autoclaves and compression molding presses handle heat, pressure, and curing cycles.

- Testing Instruments: Mooney viscometers, moving die rheometers, hardness testers, and tensile machines monitor quality at every stage.

Standardized Manufacturing Workflow

- Mixing and Maturation

- Pre-forming

- Molding and Layer Bonding

- Hot Vulcanization

- Cooling and Stabilization

- Post-processing and Finishing

- Final Inspection and Packaging

During vulcanization, temperature, pressure, and curing time must be precisely controlled, especially for large cylindrical fenders or cone-type marine rubbers where thicker sections require longer heat penetration.

Critical Parameters in Hot Vulcanization

Achieving consistent quality requires tight control over several factors:

- Temperature: Typically ranges between 140°C and 170°C, adjusted according to compound design.

- Pressure: Steam or mold pressure ensures uniform heat transfer across the entire fender body.

- Curing Time: Calculated based on product thickness, often following the “thickness-squared rule.”

- Heating Curve Control: Prevents air bubbles and uneven curing, especially in thicker rubber fenders.

- Avoiding Overcuring or Undercuring: Rheometer data ensures the curing window is optimized for mechanical strength and elasticity.

Quality Control and Testing

Strict quality assurance protocols guarantee that every marine rubber fender meets international performance standards:

Raw Material Testing

- Mooney viscosity

- Scorch safety

- Rubber hardness consistency

Process Control

- Real-time monitoring of vulcanization curves

- Batch traceability for each fender

Finished Product Tests

- Hardness Test (Shore A)

- Tensile & Tear Strength Tests

- Energy Absorption and Reaction Force Verification

- Bonding Strength between Rubber and Steel Inserts

- Accelerated Aging Tests: ozone, salt spray, and UV exposure

Common Defects and Troubleshooting

| Defect | Possible Cause | Solution |

|---|---|---|

| Air bubbles | Rapid heating, moisture | Pre-dry compounds, adjust heating curves |

| Poor adhesion | Improper steel preparation | Improve sandblasting and adhesive system |

| Undercuring | Insufficient temperature | Increase curing time or temperature |

| Sticky surface | Incorrect accelerator ratio | Optimize compound formulation |

Hot Vulcanization vs. Cold Bonding Repairs

| Aspect | Hot Vulcanization | Cold Bonding Repair |

|---|---|---|

| Bonding Strength | Very high | Moderate |

| Durability | Up to 10+ years | 1–3 years |

| Energy Absorption | Fully restored | Limited |

| Cost | Higher upfront | Lower |

| Application Scenario | Factory production | On-site emergency repairs |

For critical infrastructure like ports and offshore terminals, factory-made, vulcanized rubber fenders are always the safest and most reliable option.

Conclusion

The hot vulcanization process is the backbone of producing high-performance marine rubber fenders. Through advanced compound design, precise process control, and rigorous quality testing, manufacturers can deliver rubber fenders that provide:

- Superior energy absorption

- Excellent weather and ozone resistance

- Strong bonding with internal steel structures

- Long-term reliability under extreme marine conditions

Choosing fenders made with optimized hot vulcanization technology ensures safer berthing operations and lower long-term maintenance costs.

FAQ

1. Why is hot vulcanization essential for marine rubber fenders?

It transforms raw rubber into a durable, elastic material with superior energy absorption and weather resistance.

2. What is the typical vulcanization temperature?

Usually between 140°C and 170°C, depending on fender thickness and rubber compound.

3. What’s the difference between steam autoclave curing and compression molding?

Autoclaves suit large and thick fenders, while compression molding is ideal for smaller products.

4. How to avoid bonding failures?

Proper steel surface preparation, adhesive selection, and accurate curing parameters are critical.

5. Can cold bonding replace hot vulcanization?

No. Cold bonding is suitable for temporary repairs but cannot match the strength and durability of factory hot vulcanization.