Introduction 🌊

In port construction and ship docking, fenders play a key role. They help protect both ships and docks by absorbing impact and preventing damage. One popular type is the Wing Rubber Fender. Its special wing-shaped design provides great shock absorption and strong installation support. It’s a smart choice for small ports and workboat terminals.

What Is a Wing Rubber Fender?

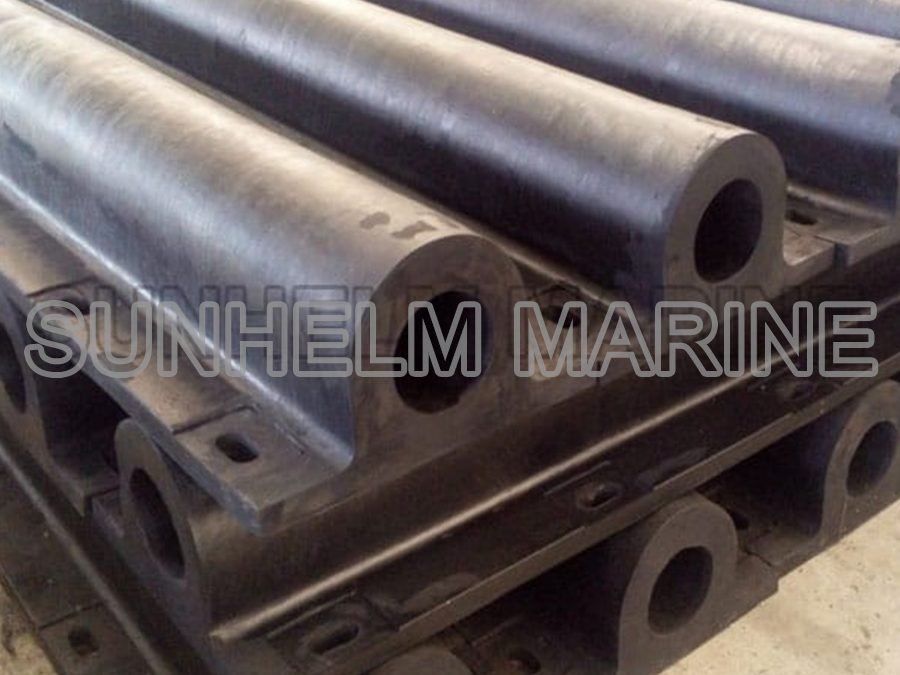

Shape and Structure

A Wing Rubber Fender (also called a GD type fender) is based on the D-shaped fender, but with two “wings” added on the base. It often has a hollow “O” shape in the center and can also be made as a solid type. These wings make it easier and stronger to mount on docks or steel frames.

Materials

Sunhelm offers fenders made from high-quality rubber like natural rubber, SBR, EPDM, or polyurethane. These materials resist seawater, sunlight, and ozone, helping the fender last longer.

Key Benefits

High Energy Absorption, Low Reaction Force

The wing shape spreads impact force over a larger area. This allows the fender to absorb more energy while reducing pressure on the ship’s hull.

Strong Installation Support

Thanks to the wide wing base and inner steel plates, Wing Rubber Fenders can be bolted firmly into place. They stay steady, even under heavy loads.

Flexible Custom Options

Sunhelm can customize fenders by size, shape, color, and hole positions. They also offer pre-curved and solid options for special dock designs.

Long-Lasting Performance

These fenders are made to survive harsh marine environments. They resist UV light, saltwater, and weather changes, keeping them in top shape for years.

Where Can You Use Wing Rubber Fenders?

Wing fenders are perfect for:

- Small ports and working docks

- Frame-type piers and steel structures

- Tugboats, ferries, and patrol boats

- Shore platforms and shipyards

They work especially well where frequent docking and reliable protection are needed.

Why Choose Sunhelm?

Certified Quality

Sunhelm’s wing fenders meet ISO 9001 and PIANC standards. They are also tested and approved by third parties like BV, SGS, CCS, and TUV.

Custom-Made for Your Needs

We can adjust the rubber type, size, shape, and installation method. Whether you need solid, hollow, or special mounting holes — we’ve got you covered.

Trusted Worldwide

With over 20 years of experience, Sunhelm supplies products to more than 70 countries. Our marine fenders are trusted by shipyards, port authorities, and offshore contractors worldwide.

Full Technical Support

From design advice to installation guides and after-sales help — we support you every step of the way.

Sizes and How to Choose

Rubber Hardness (Shore A)

Sunhelm usually uses 60–70 Shore A hardness, but we can adjust this based on your project needs.

Standard Dimensions

Wing fenders are usually 540 mm wide and 280–300 mm tall. Lengths can reach 3 meters or more. We also offer pre-curving and cutting services.

How to Choose the Right Fender

Here are the main things to consider:

- Ship size and weight – This affects how much energy the fender needs to absorb.

- Docking speed – Higher speeds mean stronger fenders are needed.

- Dock structure and how often it’s used – Choose based on how much pressure your dock can handle.

- Weather and water conditions – Salt, sun, and cold may affect the material choice.

Conclusion

Wing Rubber Fenders are a smart and strong solution for many docking needs. Their shape gives great energy absorption and makes installation secure. Sunhelm offers high-quality, custom-made wing fenders that meet global standards.

Looking ahead, Sunhelm is also working on new materials and smart fender solutions. Our goal is to offer safer, greener, and longer-lasting protection for ports and ships around the world.

If you want to know more about product models, installation drawings, or need technical support, feel free to reach out to us.