If you work in a port, shipyard, or offshore facility, you’ve probably seen pneumatic fenders—large, inflatable marine bumpers that protect ships and docks during berthing. They’re strong, durable, and surprisingly flexible in handling.

But here’s a common question from vessel operators and port managers:

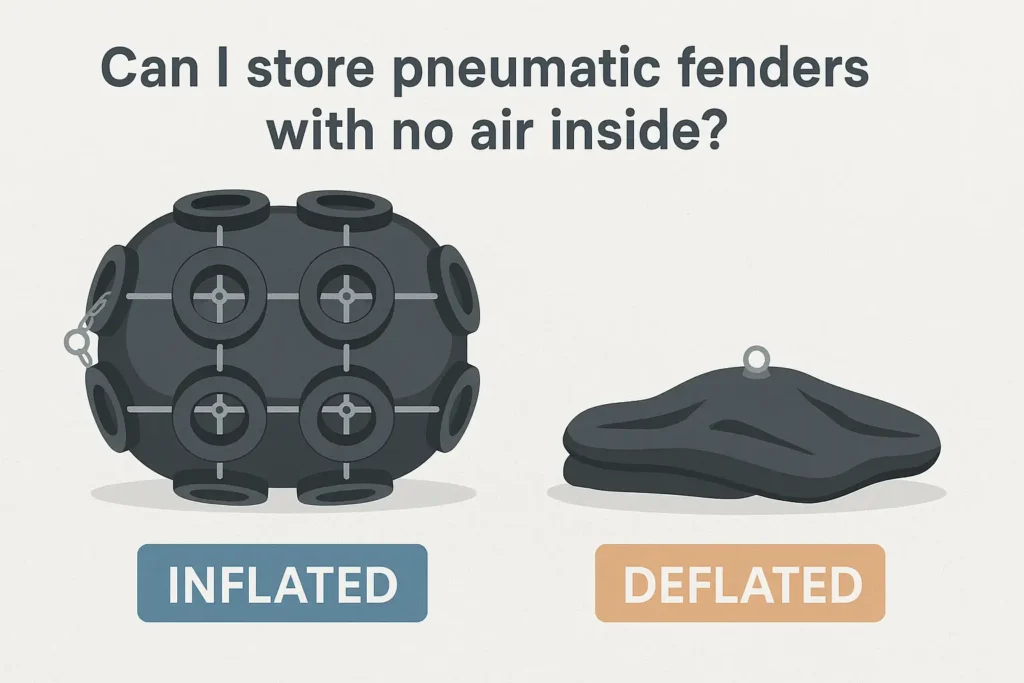

Can you store pneumatic fenders with no air inside?

The short answer: It’s possible for short-term purposes like transportation or temporary space-saving, but not recommended for long-term storage. Doing so for extended periods can shorten the lifespan of your fenders.

Why Storing Pneumatic Fenders Deflated Is Not Recommended

Pneumatic fenders are made of multiple layers of synthetic-tire-cord-reinforced rubber. When fully inflated, the pressure keeps their shape and evenly distributes stress.

If you keep them deflated for a long time:

- Material deformation – The rubber folds, creases, and compresses, creating stress points that can lead to cracks or leaks.

- Seal and valve issues – Long-term deflation can allow moisture or debris to enter valves, increasing the risk of leaks when reinflated.

- Environmental damage – UV rays, ozone, temperature fluctuations, and chemicals can still affect the rubber—sometimes more severely when the fender is folded and certain areas are under tension.

- Pest or abrasion risks – In some storage environments, rodents, sharp edges, or rough surfaces can cause unnoticed damage to a folded fender.

Manufacturer guidelines (including ISO 17357 references) consistently state that pneumatic fenders should be stored inflated for long periods to maintain their integrity.

When Is It Okay to Deflate Pneumatic Fenders?

While not suitable for long-term storage, there are valid reasons to deflate pneumatic rubber fenders:

- Transport efficiency – Shipping deflated fenders saves significant space and cost.

- Temporary storage on deck – When vessel space is limited, fenders may be deflated for a short voyage before being inflated again.

- Emergency relocation – If a port or ship needs to move multiple fenders, deflating them quickly can make handling easier.

Rule of thumb: If deflated, aim to reinflate and inspect them within a few weeks—the sooner, the better.

Best Practices for Long-Term Fender Storage

For long-term storage, keeping pneumatic fenders inflated at low pressure (typically around 20 kPa) is the safest choice. Here’s how to do it right:

- Maintain shape and internal pressure

- Store inflated at recommended pressure levels to prevent creasing and stress damage.

- Periodically check air pressure—at least every 3–6 months.

- Choose the right environment

- Store in a cool, dry, ventilated area away from direct sunlight.

- Ideal storage temperature: below 25°C (77°F).

- Keep away from ozone-generating equipment (like electric motors) and chemicals such as solvents or oils.

- Protect from contact damage

- Use pallets or wooden beams to keep fenders off the ground.

- Avoid stacking heavy objects on top.

- Ensure there are no sharp objects nearby.

- Surface preparation before storage

- Clean off salt, dirt, and marine growth.

- Dry thoroughly to prevent mold or surface degradation.

- Some manufacturers recommend applying talcum powder to reduce surface stickiness.

Onboard & Portside Storage Methods

On ships, Yokohama type fenders are often stored using:

- Fender davit systems – Mechanical arms or frames to keep fenders suspended.

- Dedicated cradles or racks – Keeps fenders upright and avoids contact damage.

- Deck folding with protection – If deflated, store in protective covers to prevent abrasion.

At ports, larger fenders are typically kept inflated on dedicated stands or floating in sheltered berths for quick deployment.

Inspection & Maintenance During Storage

Whether inflated or deflated for short-term storage, regular checks are essential:

- Air pressure monitoring – If inflated, check every 3–6 months and top up as needed.

- Surface inspection – Look for cuts, cracks, embedded debris, or UV damage.

- Valve condition – Ensure no corrosion, debris, or leaks.

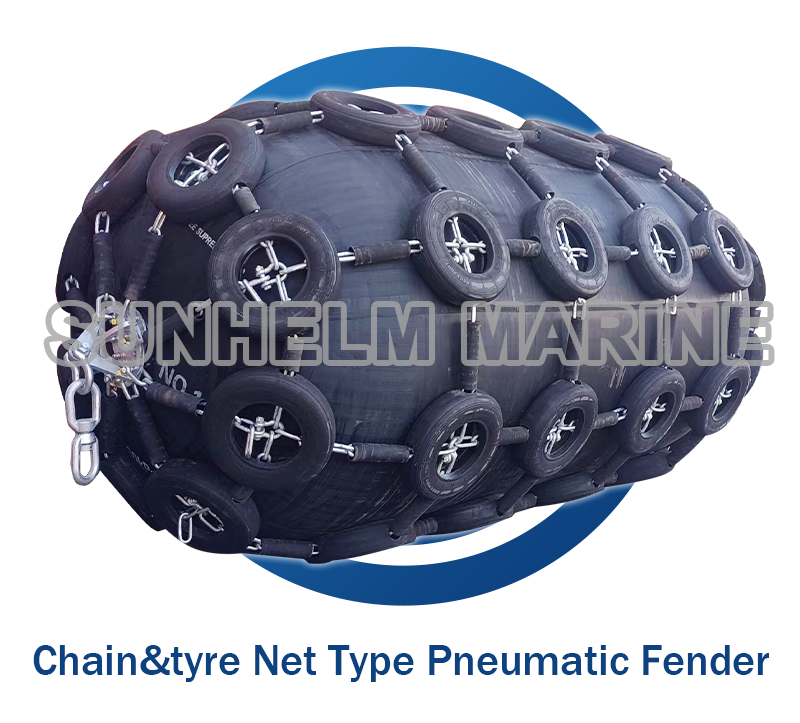

- Net and chain gear – If your fender has a tire net, check for corrosion and worn chains.

Industry Standards & Guidelines

The ISO 17357 standard specifies design, performance, and testing requirements for pneumatic fenders, including recommendations for handling and storage. Manufacturers like Trelleborg, ShibataFenderTeam, and Sunhelm align with these guidelines, emphasizing inflated storage whenever possible.

FAQ

Q1: Will storing pneumatic fenders deflated damage them immediately?

A: Not immediately, but prolonged deflation increases the risk of material deformation and damage.

Q2: How long can I store a deflated fender safely?

A: Ideally, less than a few weeks. Always inspect and reinflate before use.

Q3: Can I fold a fender when deflated?

A: Yes, for shipping or short-term space-saving, but fold gently and avoid sharp bends.

Q4: What’s the best temperature for storage?

A: Below 25°C, in a shaded and ventilated area.

Q5: Do I need to clean a fender before storage?

A: Yes—salt, dirt, and moisture can accelerate rubber degradation.

Conclusion

You can store pneumatic fenders deflated—but only for short periods and with care. For long-term storage, keeping them lightly inflated in a controlled environment is the best way to preserve their lifespan and performance.

If you want to keep your investment safe, follow the manufacturer’s storage recommendations, perform regular inspections, and handle your fenders with the same care you’d give any other critical marine asset.