Choosing the right fender system becomes much more important when a port has a large tidal range. When water levels move up and down several meters, the contact point between the ship and the berth also changes. If the fender cannot cover this full height or cannot keep stable performance across the whole tide cycle, the ship or the quay may be damaged during berthing or mooring.

This article explains how tides affect fender selection and gives clear suggestions on which fenders work best for these challenging locations.

Why Tidal Range Matters

A big tidal range creates two key problems:

- The ship contacts the berth at different heights.

The fender must cover all these possible contact points. - Energy absorption must stay consistent throughout the tide.

No matter if the water is high or low, the fender needs to protect both the ship and the quay with safe, stable reaction force.

If the fender system cannot do this, the ship may hit the quay directly at low tide or ride above the fender at high tide.

Best Fender Options for Large Tidal Range

1. Pneumatic Fenders – The Best Overall Choice

Pneumatic fenders (floating fenders) are usually the first choice for ports with large tidal differences.

Why they work well:

- They float, so they move up and down with the tide.

- They always meet the ship at the right height.

- They provide high energy absorption and low reaction force.

- They work well for large ships, STS transfers, oil terminals, and busy commercial ports.

Pneumatic fenders also reduce the risk of hull damage, especially for ships with sensitive coating systems.

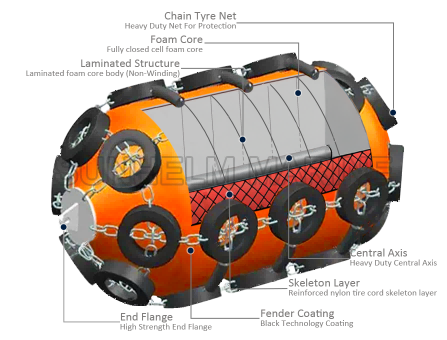

2. Foam-Filled Floating Fenders – A Strong Alternative

Foam-filled fenders are also floating fenders, so they cover the full tidal range like pneumatic fenders. They are solid inside, so they do not lose performance even if the outer skin is damaged.

Benefits:

- No air pressure maintenance

- Full tide coverage

- Strong and durable

- Good for busy berths and heavy daily operations

Ports often use them when they prefer low maintenance but still want a floating system.

3. Cone Fenders / High-Deflection Rubber Fenders – Good for Fixed Quays

If floating fenders are not suitable for the site, some large rubber fenders can still work well—especially cell-type or super-cone fenders.

Why they help:

- They offer high energy absorption.

- They can be installed in tall frames to cover more vertical height.

- They create a large “fender face” that works across tidal variations.

However, for very large tidal ranges, you may still need multiple rows or extra-high panels.

How to Choose the Right Fender

Use this quick decision guide:

Choose Pneumatic Fenders when:

- Tidal range is large

- Many ship types use the berth

- You need low reaction force

- You want a flexible berthing solution

Choose Foam-Filled Fenders when:

- You want a floating system but prefer low maintenance

- The berth has high daily traffic

- Long-term durability is important

Choose Cone / Rubber Fender Systems when:

- You need a fixed fender line

- The quay structure already uses framed fenders

- The tidal range is big but not extreme

- Floating fenders are not allowed or not practical

Practical Design Tips for Large Tidal Range Ports

- Measure the full tidal range clearly.

Use the highest and lowest water levels and add a safety margin. - Make sure the fender face covers the entire vertical contact zone.

For fixed fenders, this often means tall panels or multi-level fenders. - Check ship types and hull shapes.

Different ships touch the quay at different spots, especially at low tide. - Consider berthing angles and wind/current conditions.

A strong ocean current combined with big tides requires stronger fenders. - Do not forget maintenance.

Pneumatic fenders need air pressure checks; foam-filled ones need skin inspections; rubber fenders need panel and chain inspections.

Conclusion

In ports with a large tidal range, the most reliable fender systems are floating fenders, especially pneumatic and foam-filled fenders. They move with the tide and always stay aligned with the ship, giving stable and safe berthing conditions.

Cone fenders and other rubber fenders can work too, but they require careful design and sometimes multiple levels to cover the full tide.

If you want the safest and easiest solution, pneumatic fenders are usually the top choice.

FAQ

1. Do I always need pneumatic fenders in areas with large tides?

No. Foam-filled floating fenders also work very well. Pneumatic fenders are the most flexible, but the final choice depends on ship size, budget, and maintenance plans.

2. How do I know the panel height I need?

Calculate from highest tide to lowest tide, then add the height of the ship’s contact area. Most ports keep at least 0.5–1 m safety margin.

3. Can fixed rubber fenders work when the tidal range is very large?

Yes, but only with proper design. You may need tall panels or multiple levels of fenders to avoid “dead zones.”

{ “@context”: “https://schema.org”, “@type”: “FAQPage”, “mainEntity”: [ { “@type”: “Question”, “name”: “Do I always need pneumatic fenders in areas with large tides?”, “acceptedAnswer”: { “@type”: “Answer”, “text”: “Not always. Pneumatic fenders work best for large tidal range, but foam-filled floating fenders also provide full vertical coverage with lower maintenance.” } }, { “@type”: “Question”, “name”: “How do I know the fender panel height I need?”, “acceptedAnswer”: { “@type”: “Answer”, “text”: “Calculate from the highest tide to the lowest tide and add the ship’s contact height. Ports normally add 0.5–1 m as a safety margin.” } }, { “@type”: “Question”, “name”: “Can fixed rubber fenders work with a large tidal range?”, “acceptedAnswer”: { “@type”: “Answer”, “text”: “Yes. Cone or other high-deflection rubber fenders can work, but you may need tall panels or multiple levels to avoid dead zones during extreme tide differences.” } } ] }