A pneumatic fender is a floating rubber buffer—filled with compressed air—used to cushion vessels and docks during berthing. Known widely as a Yokohama‑type or floating fender, it consists of an inner airtight rubber bladder, reinforced tire‑cord layers, and an outer rubber shell.

Why This Issue Is Necessary and Urgent

Every port and ship operator knows: collisions during berthing can cause costly damage to hulls, jetties, and offshore structures. With growing global trade, berthing frequency and vessel size continue to increase. That makes reliable protection more urgent than ever.

Imagine a busy fuel transfer operation: two tankers come alongside each other in rough tide. Without proper cushioning, the hull could scrape or dent—and delays follow. Pneumatic fenders offer a flexible, floating buffer that adapts to tides and vessel motion, guarding assets and saving downtime.

Pneumatic Fenders: Key Features and Benefits

High energy absorption with gentle response

Because it uses air, a pneumatic fender absorbs collision energy progressively—yielding minimal impact to both vessel and berth.

Low hull pressure

The pressure exerted on a ship or dock is kept low and distributed evenly. This helps prevent concentrating stresses on painted hulls or fragile quay walls.

Compliant to international standards (ISO 17357‑1:2014)

All quality pneumatic fenders meet strict rules for design, testing, guaranteed energy absorption (GEA), internal pressure, materials, and safety valves.

Portable and low‑maintenance

Deflatable for compact transport and easy redeployment. Minimal upkeep is required—typically just a yearly pressure check.

Adaptable to inclined berthing and tidal shifts

Performs effectively even at angles up to 15°, and rides vertically with tides—ideal for ports with high tidal ranges.

Why Read On?

Pneumatic fenders may seem like simple floating devices—but there’s a lot more to them. How exactly do they work in different sea conditions? What makes one fender better than another? And how can you be sure you’re choosing the right size or type for your vessel or dock?

In the sections that follow, we’ll break it all down in plain English. Whether you’re a port operator, ship owner, or just curious about marine safety equipment, you’ll find practical insights and real-world examples that make technical details easy to understand.

How Do Pneumatic Fenders Actually Work?

At first glance, it’s just a rubber tube filled with air—but the science behind pneumatic fenders is surprisingly clever.

When a vessel approaches a dock or another ship, the fender compresses and absorbs the energy of the impact. Inside, the trapped air acts like a shock absorber. The more the fender compresses, the more force it pushes back with—but gradually. This “soft resistance” is what makes pneumatic fenders so effective at reducing damage.

Unlike solid rubber or foam-filled alternatives, pneumatic fenders don’t transfer a hard jolt to the hull. Instead, they cushion the impact smoothly, especially important for large tankers or delicate hulls like LNG carriers.

Types of Pneumatic Fenders and When to Use Them

There’s no one-size-fits-all. Here are the main types:

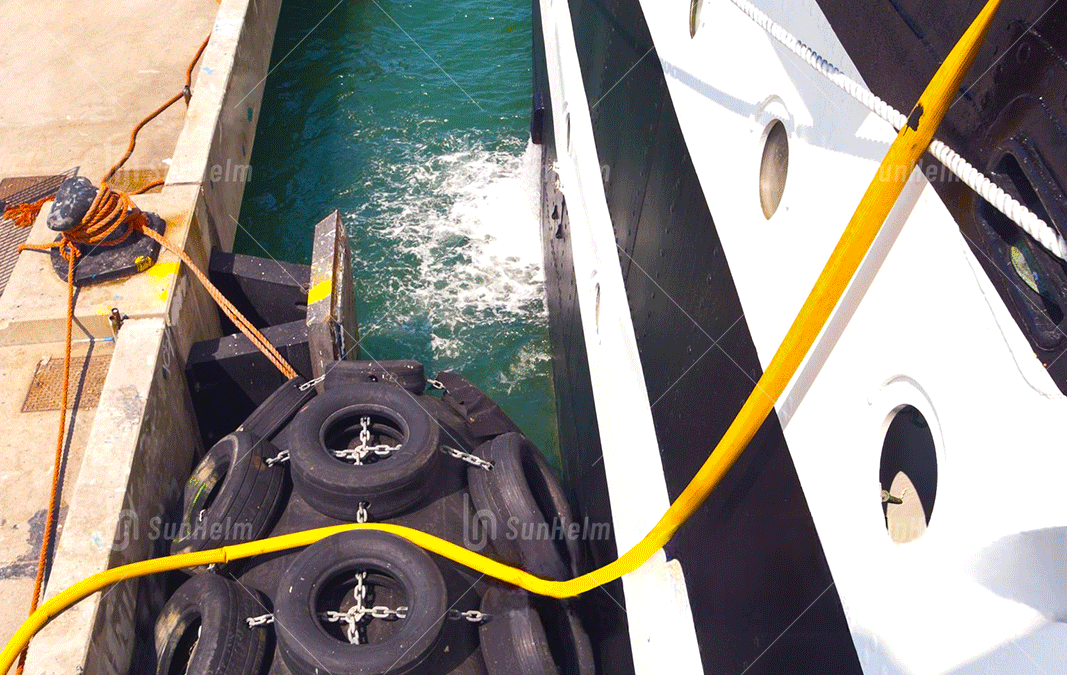

1. Chain-and-Tire Net Type

These are the most common. A heavy-duty rubber fender is wrapped in a mesh of old truck tires and chains. Great for rough berthing environments, oil terminals, or STS transfers.

2. Sling Type (No Tire Net)

Simpler and lighter. These fenders are easier to move and install—ideal for smaller ports, navy vessels, or temporary operations.

3. Hydro-pneumatic Fenders

Designed for submarines or vessels with very low or very high draft. These stand vertically in water with part air, part water inside.

Knowing when to choose each type can prevent operational headaches later. For example, using a sling-type on a crude oil tanker berth would lead to fast wear and possible hull contact. That’s why understanding the environment and load conditions matters.

FAQ

What are the differences between pneumatic fenders and foam‑filled fenders?

Pneumatic fenders are inflatable rubber units; they’re lighter, can deflate for storage, and cost less. Foam‑filled fenders don’t risk deflation but are heavier, bulkier, and generally more expensive.

How do pneumatic fenders absorb energy?

They absorb impact by compressing air within. The reaction force rises gradually—which prevents sudden jarring forces on ship hulls or berth structures.

What types of pneumatic fender are there?

The most common types are chain‑and‑tire net type (with protective mesh) and sling type (lighter, rope/chain hung). Specialized hydropneumatic versions also exist for submarines or deep‑draft vessels.

What sizes and pressure classes are available?

Diameters range from around 300 mm to 4,500 mm, lengths up to roughly 9 000 mm. Initial internal pressure typically is 50 kPa (P50) or higher at 80 kPa (P80).

How often do pneumatic fenders need maintenance?

Very little: main requirement is to check and top up air pressure once a year. Otherwise they perform reliably with minimal attention.

Next Steps with Sunhelm

At Sunhelm, we design and supply fully ISO‑compliant pneumatic fenders, tailored to your vessel size, tidal profile, and berthing configurations. Whether you seek cost‑effective standard units or hydropneumatic models for submarines or offshore platforms—we have your solution.

Contact us today for a customized proposal: we’ll walk you through size selection, guaranteed energy absorption, installation support, and service lifetime expectations.

Sunhelm combines advanced materials, smart engineering, and customer‑focused service to help ports and operators protect assets efficiently. Let us show you how a pneumatic fender from Sunhelm can streamline your operations and prevent costly damage.